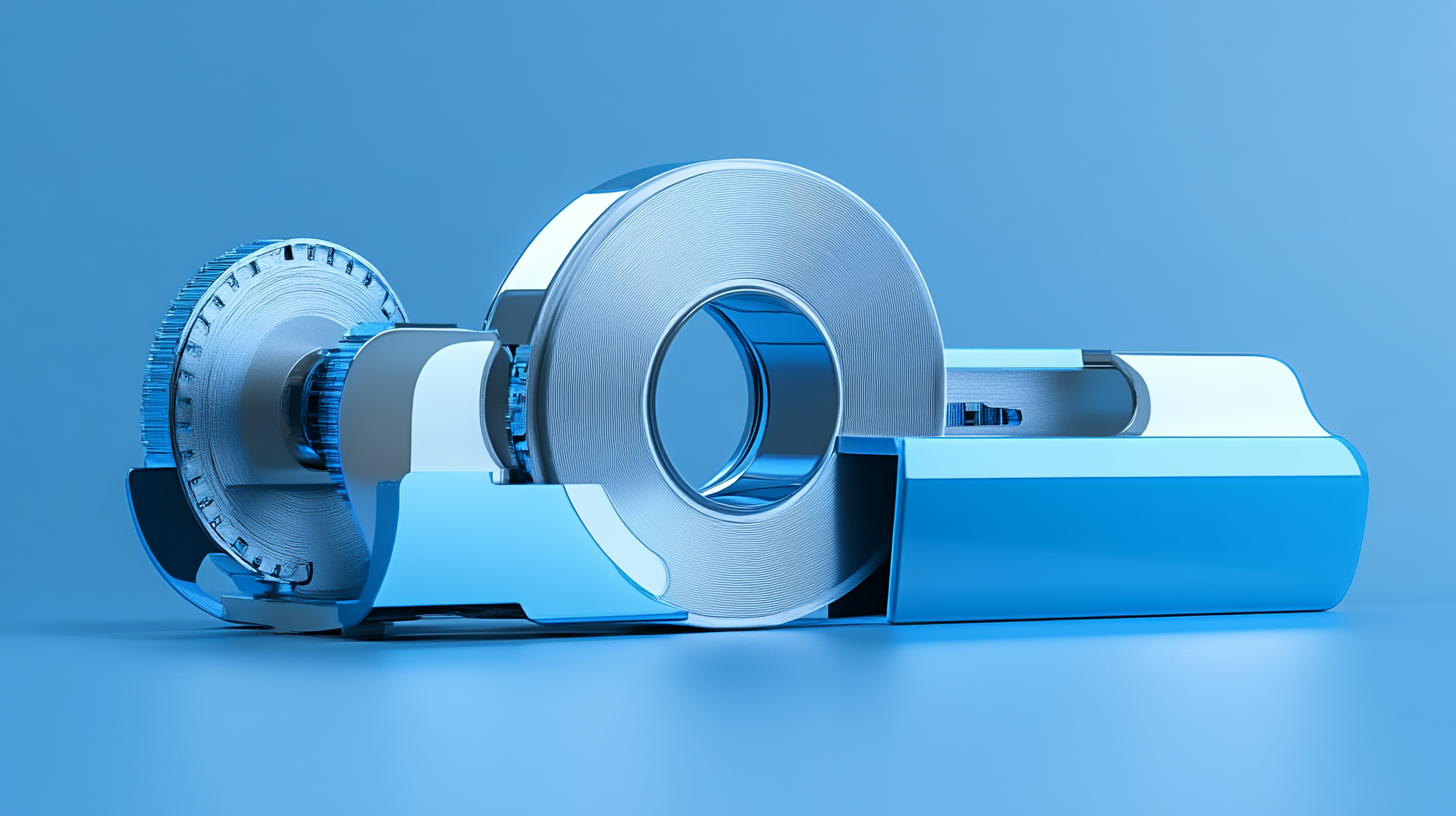

Carton Taping Machine Trends for 2025 and Best Practices for Increasing Efficiency

The carton taping machine industry is poised for significant transformation as we approach 2025. According to a report by Market Research Future, the global packaging machinery market is projected to reach $54 billion by 2025, with carton sealing and taping machinery playing a pivotal role in this growth. As businesses strive to enhance production lines and reduce operational costs, innovations in carton taping machines are becoming increasingly critical. These machines not only improve packaging efficiency but also contribute to sustainability efforts, as companies look for ways to minimize waste in their packaging processes.

As we delve into the trends that will shape carton taping machines in 2025, it is essential to highlight the best practices that can drive efficiency. The adoption of automation, integration with advanced technologies such as IoT, and the shift toward eco-friendly materials are transforming how organizations approach their packaging solutions. By embracing these trends and implementing strategic practices, businesses can position themselves to thrive in an increasingly competitive landscape. This blog will explore the key trends and actionable strategies for optimizing the use of carton taping machines in the upcoming years.

Emerging Technologies in Carton Taping Machines for Enhanced Performance

The landscape of carton taping machines is evolving rapidly, driven by advancements in technology aimed at enhancing efficiency and performance. Emerging technologies, such as machine learning and artificial intelligence, are paving the way for smarter taping solutions. These machines are now equipped with sensors that can detect carton size and adjust the taping process accordingly, minimizing waste and ensuring a precise seal every time. This level of automation not only speeds up operations but also reduces the likelihood of errors, allowing businesses to operate at peak efficiency. Furthermore, the integration of IoT (Internet of Things) capabilities into carton taping machines offers an unprecedented level of connectivity. This allows for real-time monitoring and data analysis, giving operators insights into performance metrics and potential maintenance needs. As a result, companies can optimize their production lines, anticipating issues before they become problems, which ultimately reduces downtime and improves overall productivity. Another noteworthy trend is the shift towards eco-friendly materials. Companies are increasingly seeking taping solutions that utilize sustainable adhesives and recyclable packaging materials. This innovation not only meets consumer demand for sustainability but also aligns with corporate social responsibility goals. By adopting these eco-friendly technologies, businesses can enhance their brand image while contributing positively to the environment, making it a win-win situation in the carton taping industry.

Sustainable Practices in Carton Taping: Eco-friendly Materials and Processes

As industries increasingly prioritize sustainability, the carton taping sector is also evolving to incorporate eco-friendly practices. Research indicates that the global eco-friendly packaging market is projected to reach USD 632 billion by 2024, growing at a CAGR of 5.6% (Smithers Pira). This shift offers packaging companies a pivotal opportunity to adopt sustainable materials and processes, especially in carton taping operations.

One of the significant trends is the use of biodegradable and recyclable tape options. Traditional adhesive tapes are often made from petroleum-based materials, which contribute to environmental degradation. In contrast, companies are now exploring plant-based adhesives and recycled paper tapes. For instance, a recent survey revealed that 67% of consumers are more likely to purchase products if they are delivered in eco-friendly packaging (Trivium Packaging, 2022). This consumer preference not only drives demand but also encourages businesses to rethink their packaging strategies.

Furthermore, integrating efficient packaging machinery designed for sustainable practices can lead to improved operational efficiency while lowering environmental impact. Advanced carton taping machines that reduce material waste and enhance energy efficiency are gaining traction. According to a report by MarketsandMarkets, the market for automated packaging machines that focus on sustainability is expected to grow significantly, emphasizing the importance of investing in technology that aligns with eco-conscious initiatives. Companies that embrace these trends are likely to enhance their brand image and cater to the growing consumer demand for sustainable practices.

Data-Driven Insights: Leveraging Analytics to Optimize Taping Efficiency

In the ever-evolving landscape of packaging technology, data-driven insights are becoming increasingly crucial for optimizing carton taping efficiency. As companies prepare for 2025, harnessing the power of analytics can provide significant advantages over competitors. By leveraging data from various stages of the taping process, businesses can identify inefficiencies and areas for improvement. Real-time monitoring allows for adjustments on-the-fly, ensuring that production is both swift and precise.

Another key aspect of utilizing analytics is predictive maintenance. By analyzing machine performance data, companies can foresee potential issues before they become costly disruptions. This proactive approach minimizes downtime and maximizes output. Moreover, understanding patterns in machine operation can guide training programs for employees, enhancing skill sets related to specific machinery.

Implementing these data-driven strategies not only streamlines operations but also fosters a culture of continuous improvement. As organizations gather insights about their taping processes, they can refine techniques and adopt best practices tailored to their unique needs. This focus on analytics as a driving force in carton taping will be pivotal as industries aim for efficiency and sustainability in the upcoming years.

Workforce Training: Empowering Employees for Better Machine Operation

In the fast-evolving landscape of carton taping machines, the significance of workforce training cannot be overstated. As technology advances, operators must be equipped with the skills necessary to maximize the efficiency and performance of these machines. According to a report by the Association for Packaging and Processing Technologies (PMMI), plants that invest in employee training see a 25% increase in productivity and a 30% reduction in machine downtime. This highlights the critical role that effective training plays in enhancing operational efficiency.

Implementing robust training programs not only empowers employees but also fosters a culture of continuous improvement within the workforce. A study by the International Society for Automation (ISA) indicates that companies prioritizing employee education can achieve up to 35% higher efficiency rates in production lines. By providing comprehensive training sessions focused on both the technical aspects of carton taping machines and best practices in operation, employers can significantly enhance their staff’s proficiency, leading to better handling of machinery and reduced error rates.

Furthermore, as manufacturers increasingly adopt automation and advanced technologies in carton sealing processes, the need for skilled operators becomes even more pronounced. A report from the Manufacturing Institute reveals that nearly 70% of manufacturers express concern about the skills gap impacting their operations. By investing in targeted workforce training initiatives, companies can not only bridge this gap but also ensure that their teams are well-versed in the latest operational strategies, driving overall productivity and operational excellence.

Future-Proofing Your Packaging Line: Trends to Watch Beyond 2025

As the packaging industry evolves, future-proofing your packaging line becomes crucial to staying competitive in the market. One key trend to watch beyond 2025 is the integration of smart technology within carton taping machines. These advanced systems, equipped with sensors and AI, can monitor production in real-time, optimizing process efficiency and reducing downtime. By adopting machine learning algorithms, companies can predict maintenance needs, thereby enhancing the longevity of their equipment and minimizing unexpected failures.

Another significant trend is the push toward sustainability in packaging operations. In response to increasing consumer awareness and regulatory pressures, businesses are exploring eco-friendly materials and practices. Carton taping machines that utilize biodegradable or recyclable tape solutions not only align with sustainable goals but also cater to a market that is progressively favoring environmentally responsible products. Adapting to these practices ensures that companies remain relevant and responsible in their operational ethos.

Lastly, flexibility in packaging lines will be essential. The ability to quickly adjust to different carton sizes and products can significantly increase a company's agility in response to market demands. Innovative designs in carton taping machines allow for easy reconfiguration, enabling businesses to handle diverse product lines without extensive downtime or additional costs. Embracing these trends will not only enhance operational efficiency but also better position companies to navigate the future landscape of the packaging industry.