Unlocking Efficiency: How Auto Palletizers Revolutionize Modern Warehousing

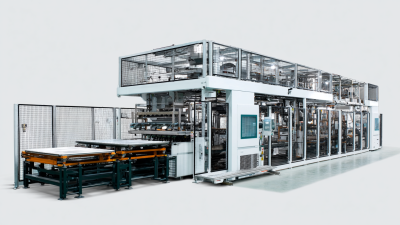

In the rapidly evolving landscape of modern warehousing, the implementation of automated systems has become essential for optimizing operational efficiency. Among these technologies, the Auto Palletizer stands out as a transformative solution, facilitating the swift and accurate stacking of goods onto pallets. According to a report by MarketsandMarkets, the global palletizing system market is expected to grow from $3.05 billion in 2020 to $4.85 billion by 2025, at a compound annual growth rate (CAGR) of 9.8%. This surge can be attributed to the rising demand for automation in warehouses, driven by the need to reduce labor costs and enhance productivity.

The Auto Palletizer not only alleviates the physical strain on workers but also minimizes the risk of errors, thereby streamlining operations and contributing to a more efficient supply chain. As businesses strive for greater agility and responsiveness, understanding how to effectively implement and leverage Auto Palletizers is crucial for maintaining a competitive edge in the industry.

The Auto Palletizer not only alleviates the physical strain on workers but also minimizes the risk of errors, thereby streamlining operations and contributing to a more efficient supply chain. As businesses strive for greater agility and responsiveness, understanding how to effectively implement and leverage Auto Palletizers is crucial for maintaining a competitive edge in the industry.

The Role of Auto Palletizers in Streamlining Warehouse Operations

In today's fast-paced logistics environment, auto palletizers play a crucial role in enhancing warehouse efficiency. By automating the process of stacking and organizing products onto pallets, these machines significantly reduce the time and labor involved in manual palletization. This streamlined process not only accelerates the loading and unloading of goods but also minimizes the risk of human error, leading to more accurate inventory management. As a result, warehouses can operate at higher throughput levels, fulfilling customer orders more quickly and effectively.

Furthermore, the implementation of auto palletizers contributes to better space utilization within warehouses. By ensuring that pallets are stacked uniformly and securely, these machines allow for optimal use of vertical storage, maximizing available warehouse space. This organization aids in simplifying the retrieval process for forklifts and other machinery, making it easier for workers to locate and access items as needed. Overall, auto palletizers are integral to modern warehousing strategies, providing the necessary tools for businesses to adapt to evolving market demands while maintaining operational excellence.

Benefits of Implementing Auto Palletizers in Supply Chain Management

In today's fast-paced supply chain landscape, the adoption of auto palletizers is a game-changer for enhancing operational efficiency. According to a recent report by McKinsey, companies that integrate automation into their warehouses can improve productivity by up to 30% while reducing labor costs by approximately 20%. Auto palletizers streamline the packing process, effectively managing the high volume and variety of goods that modern warehouses handle. This level of efficiency is crucial as supply chains increasingly face fluctuations in demand and SKU diversity.

Moreover, the implementation of auto palletizers contributes to improved safety in the workplace. The Occupational Safety and Health Administration (OSHA) reports that automated systems reduce manual handling injuries by over 40%, allowing workers to focus on more strategic tasks rather than repetitive lifting. As businesses seek to mitigate risks and enhance workplace conditions, auto palletizers emerge as a viable solution that not only boosts productivity but also prioritizes employee well-being. With the ability to optimize space utilization and maintain consistency in loading practices, the benefits of auto palletizers are undeniable in the evolution of supply chain management.

Technological Innovations Driving Auto Palletizer Efficiency

The advent of auto palletizers has ushered in a new era of efficiency in modern warehousing. These technological marvels automate the process of stacking products onto pallets, drastically reducing labor costs and minimizing human error. With the integration of advanced robotics and artificial intelligence, auto palletizers are designed to handle a wide range of products, from fragile items to heavy crates, ensuring that every pallet is assembled with precision and speed.

Tips for optimizing your auto palletizer setup include conducting regular maintenance checks to ensure all components are functioning at peak performance. Additionally, integrating sensors and software that monitor palletizing patterns can help identify bottlenecks in the workflow. This data-driven approach not only enhances efficiency but also allows for real-time adjustments, ensuring the system adapts to fluctuating demands.

As technological innovations continue to evolve, features such as machine learning capabilities are becoming more prevalent in auto palletizers. These systems can learn from past performance and improve their operations over time, reducing downtime and increasing throughput. By staying abreast of these advancements, warehouses can leverage auto palletizers to achieve unparalleled efficiency and adaptability in an increasingly competitive market.

Comparative Analysis: Manual vs. Automated Palletizing Solutions

In today's fast-paced warehousing environment, the choice between manual and automated palletizing solutions greatly affects operational efficiency. Manual palletizing often involves labor-intensive processes where warehouse workers stack products onto pallets based on predetermined patterns. While this method is flexible and allows for easy adaptation to various products and container sizes, it typically suffers from inconsistencies in stacking precision and higher labor costs.

In today's fast-paced warehousing environment, the choice between manual and automated palletizing solutions greatly affects operational efficiency. Manual palletizing often involves labor-intensive processes where warehouse workers stack products onto pallets based on predetermined patterns. While this method is flexible and allows for easy adaptation to various products and container sizes, it typically suffers from inconsistencies in stacking precision and higher labor costs.

On the other hand, automated palletizers leverage advanced technology to streamline operations. These machines can handle high volumes and maintain precise stacking patterns, significantly reducing the risk of error and damage. Furthermore, automated systems can operate continuously without the fatigue associated with manual labor, leading to higher throughput and optimized resource management.

Tip: When considering the switch from manual to automated palletizing, evaluate the specific needs of your warehouse operations. A pilot program can provide insights into how well automated solutions integrate with existing processes while allowing for adjustments before a full-scale implementation.

Tip: Invest in training for your staff to ensure they are well-versed in operating and maintaining the automated systems. This not only enhances productivity but also minimizes downtime due to operational errors.

Future Trends in Auto Palletizing and Warehousing Automation

The future of auto palletizing and warehousing automation is poised for remarkable transformation driven by advancements in artificial intelligence and robotics. As warehouses increasingly adopt smart technologies, auto palletizers are evolving from simple mechanical units to sophisticated systems capable of real-time decision-making. These innovations not only enhance efficiency but also reduce the risk of human error, vital for maintaining productivity in high-demand environments. With machine learning algorithms analyzing workflow patterns, auto palletizers can optimize their operation to adapt to fluctuations in supply and demand seamlessly.

Another trend shaping the future of this sector is the integration of Internet of Things (IoT) devices. By leveraging IoT, auto palletizers can communicate with other systems across the supply chain, enabling greater visibility and control over inventory levels and equipment performance. This interconnectedness leads to predictive maintenance, minimizing downtime and improving overall operational efficiency. Additionally, as sustainability becomes a focal point for industries, eco-friendly auto palletizing solutions will emerge, with energy-efficient designs and materials that align with greener warehouse practices, paving the way for a more sustainable future in logistics and warehousing.

Unlocking Efficiency: The Impact of Auto Palletizers on Modern Warehousing

Related Posts

-

Discovering Innovative Alternatives to the Best Automatic Case Sealer for Your Packaging Needs

-

Adhering to Industry Standards: How to Choose the Best Automatic Case Sealer for Optimal Efficiency

-

Ultimate Checklist for Choosing the Right Automatic Box Taping Machine

-

Understanding the Benefits of Automatic Palletizer Machines for Your Production Line

-

Revolutionizing Logistics with Automated Palletizers at China Import and Export Fair 2025

-

Navigating Global Trade Challenges with the Best Box Taping Machine from China