The Evolution of Automatic Box Taping Machines in Global Supply Chains

In the fast-paced world of global supply chains, the efficiency of packaging processes plays a crucial role in maintaining competitiveness and customer satisfaction. One of the key innovations that have significantly transformed these processes is the Automatic Box Taping Machine. This advanced technology not only automates the tedious task of sealing boxes but also enhances productivity and reduces labor costs. As supply chains continue to evolve in response to growing demands and challenges, understanding the evolution and impact of such machinery becomes essential for businesses striving to optimize their operations.

From their humble beginnings to the sophisticated models available today, Automatic Box Taping Machines have undergone remarkable changes, driven by technological advancements and the shifting needs of industries. As companies expand their reach across borders, the reliability and speed provided by these machines have become indispensable. This blog will explore the journey of Automatic Box Taping Machines, highlighting their development and how they have reshaped supply chain practices globally, ensuring that businesses can keep pace in a dynamic marketplace.

The Historical Development of Box Taping Machines in Supply Chain Management

The evolution of box taping machines has significantly impacted supply chain management, particularly in the context of historical developments within major retail sectors. From their inception, these machines were designed to enhance efficiency in packaging processes, reflecting the broader trends in industrial automation and supply chain optimization that have emerged since the early 20th century. As businesses grew and consumer demand increased, manual taping processes became a bottleneck. The introduction of automatic box taping machines in the mid-20th century revolutionized operations, allowing companies to streamline their packaging lines. According to a recent industry report, the global market for automated packaging machinery, including taping machines, is projected to grow by over 4% annually, indicating a strong shift towards automation in supply chains aimed at minimizing labor costs and maximizing production speed. The historical journey of major retailers highlights this transition. For instance, as one well-known home-improvement chain evolved from a small family-owned hardware store to a large retailer, the adoption of automatic box taping machines played a critical role in scaling operations. By integrating advanced packaging technologies, these retailers not only increased their operational efficiency but also improved accuracy in inventory management, further boosting their competitive edge. Industry data shows that automating packaging processes can reduce tape usage by up to 20%, a significant saving for large distribution centers. Moreover, the labor costs associated with manual packaging can account for a substantial percentage of overall logistics expenses, making the shift to automated systems necessary for thriving in the fast-paced retail environment. As supply chains continue to evolve, the role of automatic box taping machines remains pivotal in ensuring efficient and effective logistics solutions.

Current Market Analysis: The Revenue Growth of Automatic Taping Machines

The current landscape of automatic taping machines reflects a burgeoning market poised for significant growth. According to recent forecasts, the tape banding machine market alone is expected to exceed USD 3.5 billion by 2032, driven by an increasing emphasis on ensuring product safety during shipping and transportation. This surge is indicative of a broader trend in the global supply chains, where automation solutions like automatic box taping machines play a critical role in enhancing operational efficiency.

As industries expand and e-commerce continues to rise, the demand for reliable packaging solutions has never been greater. Automatic taping machines are at the forefront of this need, streamlining the packaging process and reducing manual labor costs. In-depth research from various market analyses has demonstrated a compound annual growth rate (CAGR) of approximately 8.5% for markets associated with innovative packaging technologies. This highlights the substantial investment opportunities available in automation and packaging machinery, with automatic taping machines set to capture a significant share of this upward trajectory.

Furthermore, aligned with the growth of automatic taping devices, other sectors such as the reflective tape market, which is predicted to experience revolutionary growth between 2025 and 2034, underscores a transformative shift toward advanced packaging solutions. As companies look to optimize their supply chains, the integration of automatic taping machinery is not only a response to current market demands but also a proactive strategy for future scalability and efficiency in packaging operations.

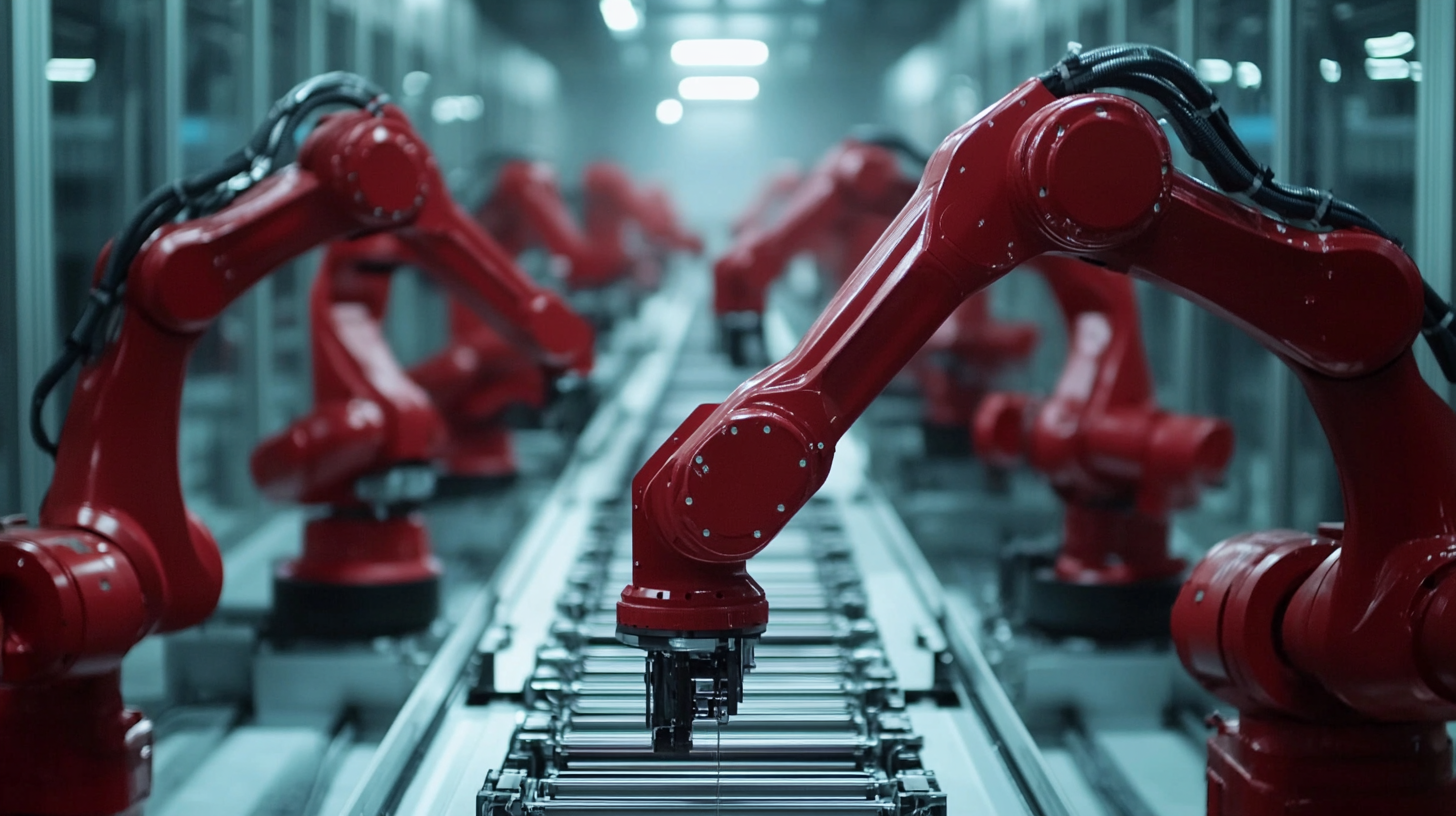

Impact of Automation on Packaging Efficiency and Labor Costs

The integration of automation in packaging processes has significantly transformed global supply chains, particularly through the use of automatic box taping machines. These advanced devices have proven instrumental in enhancing packaging efficiency, allowing companies to scale operations without compromising on quality. With the capability to handle various box sizes and materials, automatic taping machines streamline the process, reducing the time spent on manual taping and minimizing the risk of errors. This increase in efficiency enables businesses to meet rising consumer demands and maintain a competitive edge in a rapidly evolving market.

In addition to improving operational efficiency, the automation of packaging through these machines has profound implications for labor costs. As companies invest in technology, they often find that the need for manual labor decreases, allowing them to reallocate resources to more strategic roles within the organization. While some may view the shift towards automation as a threat to employment, it actually creates opportunities for workers to engage in more skilled positions that require oversight, maintenance, and management of automated systems. The reduction in labor costs associated with manual packaging processes can also lead to increased profit margins, enabling companies to invest further in innovation and customer service.

As automatic box taping machines become more sophisticated, their role in global supply chains strengthens. The balance between automation and the human touch will continue to shape the future of packaging operations, ultimately driving efficiency, lowering labor costs, and enhancing productivity across various industries. This evolution reflects a broader trend in supply chain management where technology adoption is critical for success.

Technological Innovations Driving the Future of Box Taping Machines

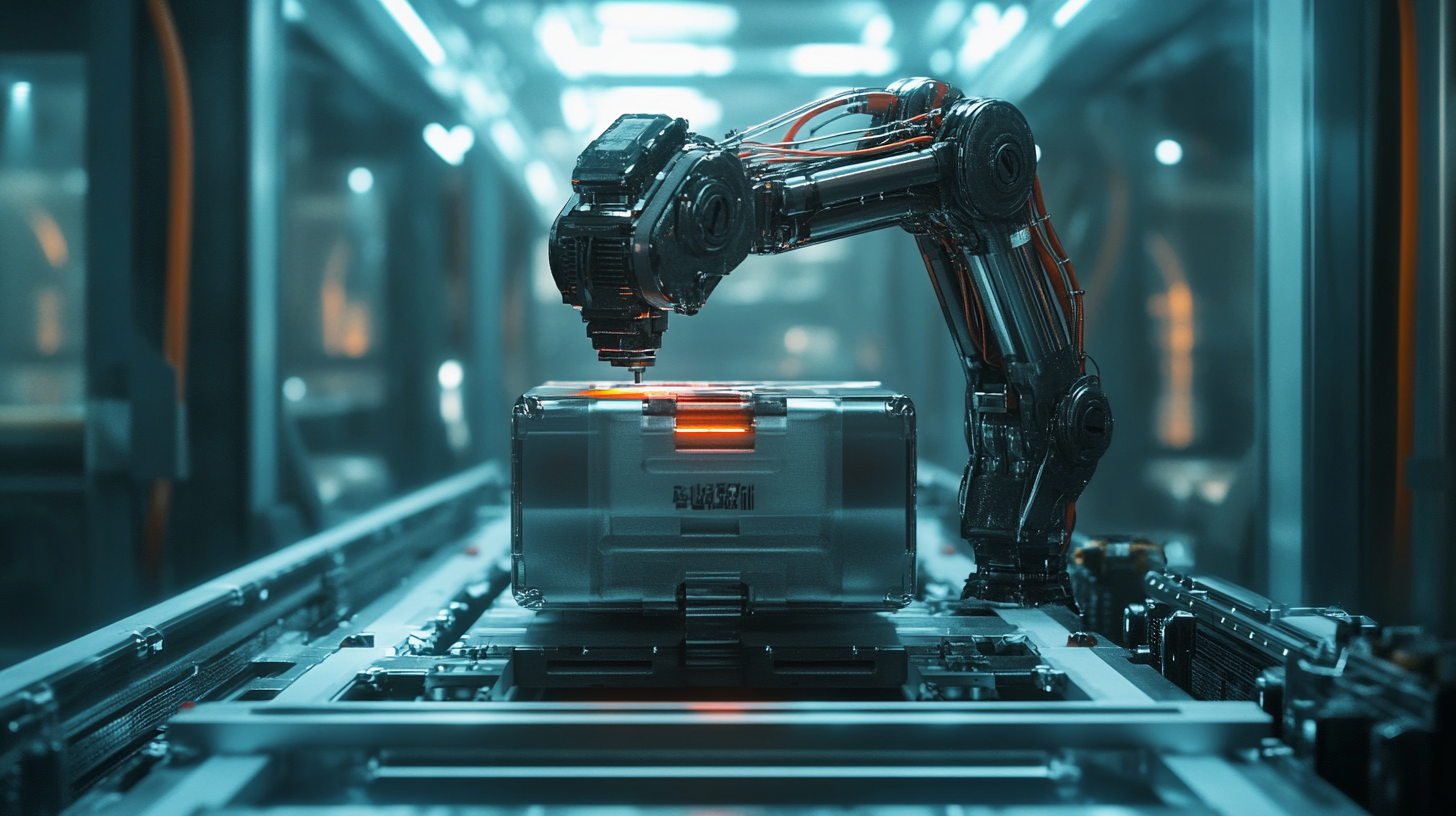

The realm of box taping machines has experienced significant technological innovations that are shaping the future of global supply chains. As businesses increasingly prioritize efficiency and accuracy, the transition from manual taping methods to fully automated solutions has become pivotal. Today's automatic box taping machines are equipped with advanced sensors and AI capabilities that enhance their operational efficiency. This technology allows for real-time adjustments, ensuring optimal tape application, reducing waste, and improving overall productivity.

Moreover, the integration of IoT (Internet of Things) in box taping machines provides unprecedented data analytics capabilities. Manufacturers can now monitor machine performance and maintenance needs remotely, leading to proactive servicing and minimal downtime. With real-time data streaming, businesses can optimize their supply chain operations, making informed decisions to adapt to fluctuating market demands. Additionally, advancements in robotic technology enable seamless integration into existing production lines, resulting in even greater flexibility and speed in packaging processes.

As e-commerce continues to grow, so too does the need for packaging solutions that can keep up with high demand. The evolution of automatic box taping machines, driven by technological innovations, is not just about efficiency; it's about enabling businesses to respond swiftly to consumer needs while maintaining sustainability within their operations. The future of packaging automation is set to be a game-changer, ensuring that companies maximize output while minimizing their environmental footprint.

The Role of Eco-Friendly Materials in The Evolution of Packaging Solutions

The push for eco-friendly materials in packaging solutions has become a pivotal trend in the evolution of automatic box taping machines within global supply chains. As industries continue to adapt to sustainable practices, the demand for packaging that minimizes environmental impact is surging. This shift is not just a response to consumer preferences; it reflects a broader recognition of the need to address pressing global environmental concerns.

Bioengineered packaging is at the forefront of this transformation, promising not only functionality but also significant reductions in ecological footprints. Companies like Sumant Singhal are pioneering innovations that align with sustainability goals, enhancing packaging efficiency while using materials that are less harmful to the planet. The integration of smart technologies further amplifies these advancements, facilitating a circular economy where materials are reused and recycled rather than discarded.

The eco-friendly food packaging market exemplifies this growing trend, with a valuation projected to soar from $197 billion in 2023 to an estimated $319 billion by 2030. This surge indicates a robust consumer shift toward sustainable products, driving manufacturers to innovate continuously. As packaging solutions evolve, the focus on eco-friendly materials will remain a cornerstone, shaping not only the way products are presented but also how businesses position themselves in a rapidly changing market landscape.