How to Choose the Best Carton Erector Machine for Your Packaging Needs

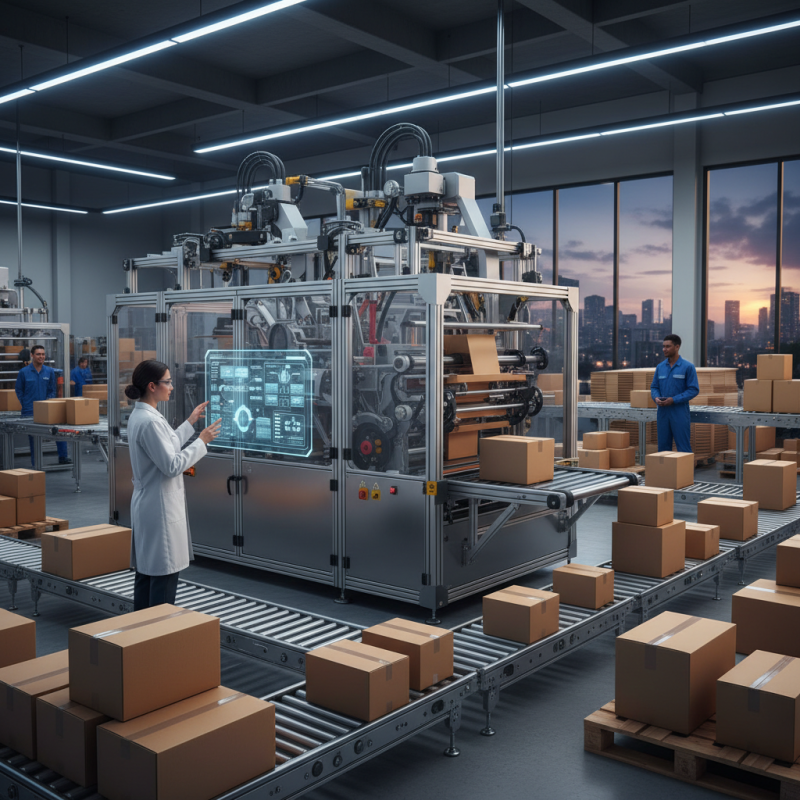

In the ever-evolving world of packaging technology, selecting the right equipment is crucial for enhancing operational efficiency. The Carton Erector Machine, a vital component in streamlining packing processes, has gained significant attention in recent years. According to Dr. Emily Chen, a leading expert in automation and packaging solutions, "A well-chosen Carton Erector Machine can drastically reduce manual labor and enhance production speed, making it an indispensable asset for modern packaging lines."

When considering a Carton Erector Machine, it is essential to evaluate various factors such as the machine's compatibility with specific carton types, production speed, and ease of operation. Additionally, understanding the unique needs of your packaging line can help in identifying the most suitable options available in the market. This article delves into key considerations and best practices to aid businesses in their quest to find the optimum Carton Erector Machine tailored to their packaging requirements.

Understanding Carton Erector Machines and Their Functions

Carton erector machines play a crucial role in the packaging industry, streamlining the process of assembling cardboard boxes for various products. These machines operate by folding and gluing flat carton blanks into three-dimensional boxes ready for filling. Understanding their functions is essential for businesses seeking efficiency and reliability in their packaging operations. According to a recent industry report by Smithers Pira, the global demand for carton erector machines is projected to grow at a CAGR of 4.5% over the next five years, driven by increased automation in packaging processes across various sectors, including food and beverage, pharmaceuticals, and consumer goods.

The functionality of carton erector machines varies by model, but key features typically include adjustable speed settings, automatic feeding systems, and compatibility with different carton sizes. Advanced models may also incorporate sensors to ensure precise alignment and minimize material wastage. This level of precision is critical; data shows that reducing packaging errors can save businesses up to 20% in material costs over time. Additionally, with the rise of e-commerce, the need for robust and durable packaging solutions has become more prominent, further underscoring the importance of selecting the right carton erector that meets specific production demands while adapting to evolving market trends.

Key Factors to Consider When Choosing a Carton Erector Machine

When selecting a carton erector machine, several key factors should be taken into account to ensure it meets your packaging needs effectively. Firstly, consider the production speed of the machine. The speed at which it can erect cartons should align with your overall production rate. An optimal machine will efficiently keep pace with your packaging line without causing bottlenecks. Additionally, examine the machine's flexibility in handling different carton sizes and styles, which is crucial if your product range varies.

Another important factor is the ease of operation and maintenance. A machine that is user-friendly will minimize the training time for operators and can quickly adapt to changing production requirements. Regular maintenance is essential for long-term reliability, so choose a machine that offers accessible parts and straightforward maintenance procedures. Finally, assess the machine’s footprint and integration capability within your existing production environment, ensuring that it can fit well without disrupting workflow. Each of these factors will play a vital role in determining the right carton erector machine for your specific packaging needs.

Assessing Production Speed and Efficiency Needs

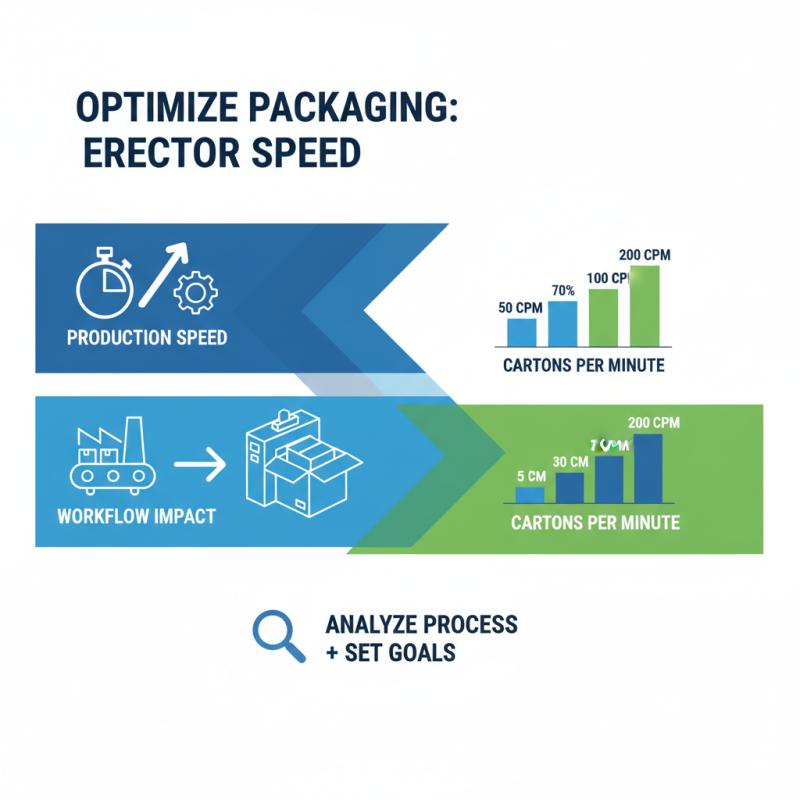

When selecting a carton erector machine, assessing production speed and efficiency needs is crucial for optimizing your packaging operations. The speed of your carton erector will directly impact your workflow; therefore, it's essential to choose a machine that aligns with your production goals. Analyze your current packaging process and determine the average number of cartons you need erected per minute. This will help you identify the required speed capacity of the machine.

Tips: Consider potential future demands; if you expect a surge in production, selecting a machine with a higher speed capacity might save you the hassle of upgrading later. Additionally, look into models that allow for easy adjustments in speed to accommodate various packaging sizes and types.

Efficiency is not solely about speed; it's also about minimizing downtime and maximizing output. A machine that requires frequent maintenance or is prone to breakdowns can disrupt your entire operation. Investigate the machine’s features such as automated adjustments and ease of integration with existing systems.

Tips: It's worthwhile to consider machines that offer user-friendly interfaces and require less manual intervention, ensuring a smoother operation and better allocation of workforce resources. Always evaluate the total cost of ownership, including maintenance and operating costs, to ensure the machine meets your efficiency standards long-term.

Evaluating Machine Size and Compatibility with Packaging Lines

When selecting a carton erecting machine, one of the primary considerations is its size and how well it integrates with your existing packaging lines. The dimensions of the machine should align with the layout of your facility, allowing for efficient workflow and minimal disruption. Moreover, it's essential to ensure that the erector can accommodate the dimensions of the cartons you intend to use, as variations in size can impact the speed and efficiency of your packaging process.

Tips for evaluating machine size include measuring the available space in your production area and considering any additional equipment that will be alongside the carton erector. Additionally, pay attention to the height, width, and depth of the machine to avoid any compatibility issues with your other packaging systems.

Furthermore, assess the machine's compatibility with your packaging lines. This involves checking if the erector can adapt to the speed and capacity of your existing equipment. A well-suited machine not only streamlines the process but also prevents bottlenecks in production. It's advisable to consult with manufacturers about the integration capabilities of the carton erector to ensure it meets your specific needs while enhancing overall operational efficiency.

Analyzing Maintenance Requirements and Support Services

When selecting a carton erector machine, it's essential to consider its maintenance requirements and the support services provided by the manufacturer. A well-maintained machine not only improves productivity but also extends the lifespan of the equipment. One key aspect of maintenance is regularly scheduled checks, which should include lubrication, adjustments, and the replacement of worn parts. This proactive approach helps prevent unexpected breakdowns and costly downtime in your packaging line.

Tips for maintenance include creating a maintenance log to track service history, implementing a cleaning schedule to reduce wear from dust and debris, and training operators to perform basic checks and adjustments. Additionally, consider the accessibility of components; machines designed for easy access can simplify maintenance tasks and reduce the amount of time your team spends on upkeep.

Support services vary by manufacturer, so it's crucial to assess the level of service offered. Look for companies that provide comprehensive training for your staff, quick access to spare parts, and a responsive technical support team. A strong support network will alleviate issues that could arise during operation and ensure that your carton erector machine remains efficient and reliable.

Related Posts

-

10 Innovative Uses of Case Tapers That Every Global Buyer Should Consider

-

How to Identify Reliable Suppliers for the Best Case Sealer Without Compromise

-

Understanding the Versatility of the Best Carton Taping Machines: Features and Applications for Diverse Products

-

Challenges Faced by Global Buyers When Selecting the Best Case Erector

-

The Ultimate Guide to Choosing the Right Carton Taping Machine for Your Packaging Needs

-

Why Every Brewery Needs a Case Packer for Efficient Packaging and Profitability