How to Choose the Right Palletizer Machine for Your Business Needs

In today's fast-paced manufacturing landscape, selecting the right Palletizer Machine is crucial for optimizing operational efficiency and meeting production demands. According to a recent report by MarketsandMarkets, the global palletizing equipment market is projected to reach $3.6 billion by 2026, growing at a CAGR of 4.5%. This growth reflects the increasing need for automated solutions in industries such as food and beverage, pharmaceuticals, and consumer goods, highlighting the importance of making informed decisions when outfitting your facility with palletizing technology.

Industry expert John Smith, a leading consultant in automation solutions, emphasizes the need for businesses to align their palletizing choices with specific operational goals: “Choosing the right Palletizer Machine is not just about cost; it’s about enhancing productivity, ensuring product safety, and adapting to evolving market demands.” His insights underline the complexity of the selection process, which must consider factors such as throughput requirements, available space, and the types of products to be palletized.

In this guide, we will delve into the essential criteria and practical considerations for selecting a Palletizer Machine that meets your business needs, enabling you to capitalize on market opportunities while maintaining efficiency and reliability in your operations.

Understanding the Different Types of Palletizers Available in the Market

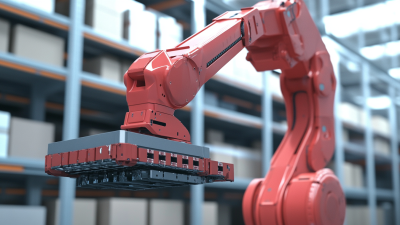

When selecting a palletizer machine, it's essential to understand the various types available in the market. The two primary categories are robotic and conventional palletizers. Robotic palletizers use articulated robotic arms to pick and place products onto pallets, offering flexibility and adaptability for different product shapes and sizes. This type is particularly beneficial for businesses with changing product lines or relatively lower production volumes, as they can be easily reprogrammed for different tasks.

Conventional palletizers, on the other hand, are typically faster and more suited for high-volume operations. They utilize mechanically driven systems to stack products, making them ideal for large-scale manufacturing environments where speed and efficiency are crucial. Businesses that require consistent, high-speed palletizing for uniform products would find conventional palletizers to be a more practical choice. Understanding these options helps businesses align their specific needs with the capabilities of each palletizing solution, ensuring optimal efficiency and productivity.

Key Factors to Consider When Choosing a Palletizer for Your Business

When selecting a palletizer machine for your business needs, there are several key factors to consider to ensure you make the right investment. First, evaluate your production volume and the types of products you handle. Different palletizers are designed for varying speeds and handling capabilities, so understanding your output requirements will help narrow down your options.

Tips: Consider how the size and weight of your products might affect the choice of palletizer. If you handle a diverse range of products, look for a machine that offers flexibility in customization. Additionally, assess whether your operations would benefit more from a robotic palletizer or a conventional one, as each comes with its advantages depending on the application.

Another essential factor is the layout of your facility. The arrangement of your production line can impact the type of palletizer you choose, so it's crucial to consider the available space and the machine's footprint. Ensure compatibility with existing equipment and workflow to maximize efficiency and minimize disruptions.

Tips: Think about future growth and scalability when making your decision. A machine that can adapt to increasing production demands will save you time and costs in the long run. It's also wise to explore the maintenance requirements of different models to ensure they align with your operational capacity.

Evaluating the Space and Layout Requirements for Palletizer Installation

When selecting the right palletizer machine for your business, evaluating the space and layout requirements is crucial. According to the Material Handling Industry (MHI), over 70% of material handling equipment failures are attributed to poor installation practices, often stemming from inadequate spatial planning. A well-designed layout ensures optimal workflow, reduces bottlenecks, and maximizes efficiency. This becomes even more important as manufacturers look to automate processes to meet rising production demands; a recent report indicated that over 60% of businesses implementing automation noted significant improvements in their operational efficiency.

Assessing your facility's dimensions—height, width, and floor space—is essential before purchasing palletizers. For instance, robotic palletizers typically require more vertical space compared to traditional models, potentially impacting your current warehouse layout. Additionally, consider the integration of surrounding equipment and how the palletizer will interact with conveyors and other machinery. The International Society of Automation suggests that carefully considering these factors can lead to a reduction in installation time by up to 30%, allowing companies to ramp up production capabilities faster while ensuring safety and compliance with industry standards.

Comparing Automation Levels: Semi-Automatic vs. Fully Automatic Palletizers

When selecting a palletizer machine for your business, understanding the differences between semi-automatic and fully automatic options is crucial. Semi-automatic palletizers are typically more affordable and offer greater flexibility, making them suitable for businesses with fluctuating production volumes. They require some manual intervention, which can be an advantage for small operations that may not maintain high throughput constantly. This type of palletizer often combines human oversight with machine efficiency, allowing operators to make adjustments quickly and react to production changes.

On the other hand, fully automatic palletizers provide a high level of efficiency and consist of sophisticated technology that can operate independently with minimal human supervision. These machines are ideal for large-scale operations that demand consistent output and require speed and precision. While the initial investment is higher, fully automatic systems offer long-term cost savings by reducing labor costs and enhancing productivity. Ultimately, the choice between semi-automatic and fully automatic palletizers will depend on your business size, production demands, and budget constraints. Evaluating these factors will help you align the palletizer’s capabilities with your operational goals.

Comparison of Semi-Automatic vs. Fully Automatic Palletizers

Assessing Long-Term Costs and Maintenance for Palletizer Machines

When assessing the long-term costs and maintenance for palletizer machines, businesses must consider several factors beyond the initial purchase price. The operational efficiency of the machine plays a critical role in calculating its total cost of ownership. This includes evaluating energy consumption, which can significantly impact utility expenses over time.

Moreover, businesses should analyze the availability of parts and service support to mitigate potential downtime, as repair costs can quickly accumulate if a machine requires specialized components or expertise.

Additionally, companies should prioritize machines that offer robust maintenance programs. Regular maintenance can extend the lifespan of palletizers and prevent costly breakdowns, making it an essential aspect of financial planning. By investing in a reliable system designed for longevity, manufacturers can better anticipate their ROI and ensure that their equipment aligns with both current needs and future growth. This strategic approach allows businesses to make well-informed decisions that balance upfront costs with long-term operational efficiency and sustainability.

Related Posts

-

The Future of Best Automatic Palletizer Machines Transforming Logistics Automation

-

Understanding the Role of Palletizer Machines in Modern Manufacturing Efficiency

-

Understanding the Benefits of Using an Automatic Palletizer Machine in Modern Warehousing

-

Unmatched Quality: China's Leading Exporter of Premier Palletizing Systems

-

How to Select the Right Carton Taping Machine for Your Business Needs

-

Ultimate Guide to Selecting the Right Palletizer Machine: Key Features and Industry Insights