How to Choose the Right Packaging Robots for Your Manufacturing Needs

In the rapidly evolving landscape of manufacturing, the integration of technology has become a cornerstone for

optimizing efficiency and productivity.

According to a report by ResearchAndMarkets, the global packaging robots market is projected to grow at a

CAGR of 12.9% from 2021 to 2026, reflecting an increasing demand

for automated solutions in packaging processes.

Packaging robots, which enhance precision, speed, and reliability, are redefining traditional practices across

various industries. However, with a myriad of options available, selecting the right packaging robots for specific

manufacturing needs can be daunting.

Factors such as load capacity, speed,

flexibility, and ease of integration

with existing systems must be carefully considered to ensure that businesses not only meet their operational goals

but also remain competitive in an increasingly automated world.

Packaging robots, which enhance precision, speed, and reliability, are redefining traditional practices across

various industries. However, with a myriad of options available, selecting the right packaging robots for specific

manufacturing needs can be daunting.

Factors such as load capacity, speed,

flexibility, and ease of integration

with existing systems must be carefully considered to ensure that businesses not only meet their operational goals

but also remain competitive in an increasingly automated world.

Understanding the Role of Packaging Robots in Modern Manufacturing Efficiency

In today’s fast-paced manufacturing landscape, understanding the role of packaging robots has become crucial in enhancing operational efficiency. According to a report by Markets and Markets, the global packaging robots market is expected to grow from $2.0 billion in 2020 to $4.4 billion by 2026, reflecting a compound annual growth rate (CAGR) of 14.8%. This growth underscores the increasing adoption of automation technologies including packaging robots, which are pivotal in streamlining processes, increasing throughput, and reducing labor costs.

Packaging robots not only boost efficiency but also improve precision in packaging tasks. With advancements in robotic technology, these systems can handle a variety of packaging formats and materials, leading to enhanced productivity. A study by the Association for Packaging and Processing Technologies highlights that companies implementing robotic packaging solutions have seen an average improvement of over 30% in their packaging line efficiency. This shift not only optimizes workflow but also helps to minimize errors and waste, allowing manufacturers to meet rising consumer demands in a competitive market.

Distribution of Packaging Robots in Manufacturing Sectors

This bar chart displays the distribution of packaging robots across various manufacturing sectors, showcasing the importance and efficiency of automation in these industries.

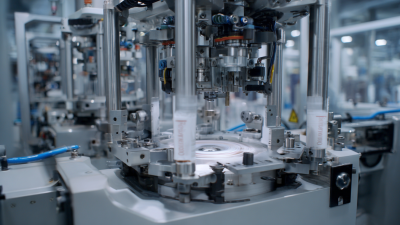

Key Factors in Selecting the Right Packaging Robot for Your Production Line

When selecting the right packaging robot for your production line, several key factors must be considered to ensure optimal efficiency and performance. First and foremost, assess the specific demands of your packaging processes. Different products require different handling methods; for instance, delicate items may need robots equipped with gentle gripping systems, while bulkier items might benefit from heavier-duty models that can manage higher payloads. Understanding the characteristics of your products will guide you towards the right robotic technology to incorporate.

When selecting the right packaging robot for your production line, several key factors must be considered to ensure optimal efficiency and performance. First and foremost, assess the specific demands of your packaging processes. Different products require different handling methods; for instance, delicate items may need robots equipped with gentle gripping systems, while bulkier items might benefit from heavier-duty models that can manage higher payloads. Understanding the characteristics of your products will guide you towards the right robotic technology to incorporate.

Another critical factor is the compatibility of the robot with your existing production line. This includes evaluating the robot’s ability to integrate with current machinery, software systems, and overall workflow. A seamless integration minimizes downtime and enhances productivity. Additionally, consider the robot's flexibility; as needs may change over time, opting for a robot that can adapt to various packaging tasks will provide long-term value to your operations. By carefully weighing these factors, manufacturers can make informed decisions that enhance efficiency and reduce operational costs.

Comparative Analysis: Types of Packaging Robots and Their Industry Applications

When it comes to selecting the right packaging robots for your manufacturing needs, understanding the different types and their industry applications is crucial. According to a report by Grand View Research, the global packaging robotics market was valued at approximately $4 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 12.1% from 2021 to 2028. This growth is attributed to the increasing demand for automation across various industries, such as food and beverage, pharmaceuticals, and consumer goods.

There are several types of packaging robots available, including Cartesian, SCARA, and delta robots, each serving distinct functions. For instance, Cartesian robots excel in applications requiring precise linear motion, making them ideal for loading and unloading tasks in the electronics sector. Conversely, delta robots offer high-speed performance for high-precision tasks, often utilized in food packaging to ensure rapid and efficient pack rates. According to the International Federation of Robotics (IFR), the food industry represented nearly 27% of the total demand for robots in packaging applications in 2021, highlighting the need for tailored solutions that align with specific operational requirements.

How to Choose the Right Packaging Robots for Your Manufacturing Needs

| Robot Type | Key Features | Industry Applications | Advantages | Limitations |

|---|---|---|---|---|

| Articulated Robots | Highly flexible with multiple joints | Automotive, Electronics | Versatile and high payload capacity | Higher complexity and cost |

| Delta Robots | High speed and precision | Food, Pharmaceuticals | Fast cycle times and accuracy | Limited range of motion |

| Collaborative Robots (Cobots) | Safe interaction with human workers | Assembly, Packaging | Easy programming and deployment | Lower payload capacity |

| Cartesian Robots | Linear movement along X, Y, Z axes | Packaging, Material Handling | Simple design and programming | Limited flexibility in routing |

| SCARA Robots | Rotational movement with vertical axis | Electronics, Assembly | High speed and precision for tasks | Limited vertical movement capabilities |

Evaluating Return on Investment (ROI) for Packaging Robot Integration

When evaluating the return on investment (ROI) for integrating packaging robots, small-to-mid-sized manufacturers (SMMs) should first consider the unique challenges they face, including budget constraints and workforce limitations. Collaborative robots, automated mobile robots (AMRs), and Robotics-as-a-Service (RaaS) models offer flexible solutions that can be tailored to the specific needs of SMMs. By focusing on the scalability of these technologies, manufacturers can assess potential cost savings and productivity gains, making informed decisions about automation.

Moreover, the cautious curiosity surrounding humanoid robots in the packaging sector reflects a broader trend among consumer packaged goods (CPGs). While there is interest in these advanced solutions, many companies are still hesitant to adopt them. This hesitance can impact ROI calculations, as the initial investment and integration costs must be weighed against the anticipated efficiencies. Therefore, SMMs must conduct thorough evaluations, modeling various scenarios to better understand the financial implications and establish a clear pathway towards automation that aligns with their goals and capabilities.

Future Trends in Packaging Robotics: What Manufacturers Need to Know

As manufacturers continue to adapt to the fast-paced demands of modern production, packaging robotics have emerged as a pivotal component in enhancing efficiency and accuracy.

Future trends in packaging robotics point towards the integration of artificial intelligence and machine learning, enabling robots to not only automate repetitive tasks but also to learn from their environment. This level of adaptability allows robots to optimize their operations dynamically, reducing waste and improving overall productivity.

Another significant trend is the rise of collaborative robots, or cobots, which work alongside human workers.

These robots are designed to assist with tasks that require precision without replacing human labor. Their ability to operate safely in close proximity to humans makes them ideal for environments where flexibility and quick adjustments are needed. Furthermore, advancements in sensor technology and vision systems are enhancing robots’ capability to identify products, manage diverse packaging requirements, and handle variations in product shapes and sizes.

Investing in advanced packaging robotics will not only streamline operations but also position manufacturers at the forefront of technological innovation.

As the industry continues to evolve, understanding these future trends will be essential for businesses aiming to remain competitive and responsive to market demands.

Related Posts

-

Maximizing Efficiency in Automated Packaging Systems with Cost Effective Maintenance Solutions

-

How to Choose the Best Packaging Machinery for Your Business Needs

-

7 Benefits of Choosing Packaging Robots for Your Business Efficiency

-

The Future of Best Packaging Machinery Integrating Automation and Sustainability Trends

-

The Future of Best Packaging Machinery: Innovations Shaping Tomorrow's Industry

-

Exploring Innovative Alternatives to Automatic Box Tapers for Efficient Packaging Solutions