Why Every Brewery Needs a Case Packer for Efficient Packaging and Profitability

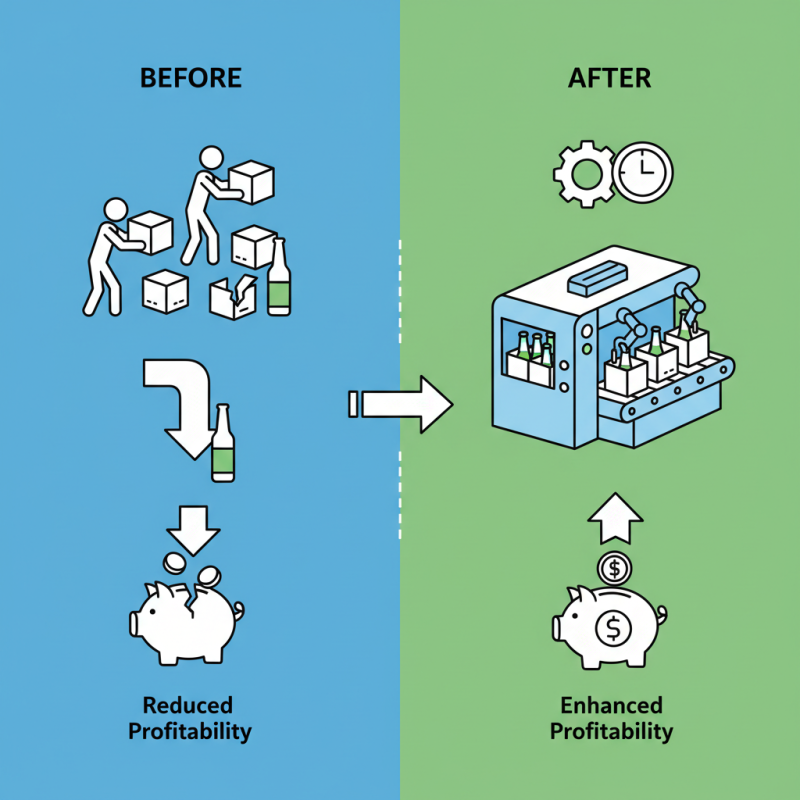

In the rapidly evolving brewery industry, efficiency and profitability are paramount. As competition intensifies, breweries must adopt innovative solutions to streamline their operations. One such solution is the implementation of a Case Packer, a pivotal piece of machinery that automates the packaging process. According to industry expert John Smith, a renowned engineer specializing in packaging solutions, "Investing in a Case Packer not only enhances operational efficiency but also significantly reduces labor costs and minimizes product damage."

The integration of a Case Packer into brewery operations can transform the packaging stage from a labor-intensive task into a seamless, automated process. This not only speeds up production but also ensures that products are packaged consistently and accurately, leading to higher quality standards and a better end-user experience. By harnessing the capabilities of modern Case Packers, breweries can focus on what they do best—creating exceptional brews—while leaving the complexities of packaging to advanced technology.

Furthermore, the financial ramifications of utilizing a Case Packer are compelling. As breweries scale operations, the importance of cost-effective packaging solutions becomes increasingly evident. With increased efficiency, reduced labor costs, and minimized waste, breweries that invest in Case Packers position themselves for sustained growth and enhanced profitability in a competitive market.

The Importance of Efficient Packaging in Breweries

Efficient packaging is a critical aspect of brewery operations that can significantly influence profitability. In an industry where competition is fierce, ensuring that your products are packaged quickly and accurately can set your brewery apart. A streamlined packaging process not only improves workflow but also reduces the likelihood of errors that can lead to product waste. Implementing automated solutions like case packers can help maintain consistency in packaging, ensuring that every case meets quality standards.

Tips for enhancing packaging efficiency include regularly training staff on new technologies and best practices. This keeps the team agile and responsive to changes in demand. Additionally, investing in high-quality packaging materials can prevent damage during transportation, reducing costs associated with returns and replacements. Finally, consider utilizing data analytics to monitor packaging processes—this can help identify bottlenecks and areas for improvement in your operation.

By prioritizing efficiency in packaging, breweries can enhance their overall productivity while also increasing customer satisfaction. Efficiency not only impacts bottom-line profits but also supports the sustainability of brewing operations, allowing for growth and innovation in a competitive marketplace.

Importance of Packaging Efficiency in Breweries

Key Benefits of Implementing Case Packers in Brewing Operations

Implementing case packers in brewing operations offers several key benefits that contribute to both efficiency and profitability. Firstly, case packers significantly streamline the packaging process by automating the arrangement of bottles or cans into cases. This not only reduces the time and labor involved but also minimizes the potential for human error, ensuring that products are packed consistently and accurately. By increasing the speed at which products are prepared for distribution, breweries can meet customer demand more effectively and avoid delays that could affect sales.

Moreover, case packers enhance overall production capacity. With the ability to handle high volumes of products with minimal supervision, breweries can allocate their workforce to other critical areas, such as quality control or product innovation. This maximization of resources not only leads to lower operational costs but also allows breweries to maintain competitive pricing in the market. In addition, the improved aesthetics associated with uniform packaging appeals to consumers, potentially boosting brand loyalty and sales. Together, these advantages make case packers an essential asset for any brewery looking to optimize its operations and enhance profitability.

How Case Packers Enhance Productivity and Reduce Labor Costs

In the fast-paced world of brewing, efficiency is key to maintaining profit margins and meeting consumer demand. Case packers play an essential role in enhancing productivity by automating the packaging process. With these machines, breweries can significantly speed up the packing of bottles and cans, reducing the time workers spend on manual packaging tasks. This increased speed not only improves throughput but also allows staff to focus on other critical areas of production, leading to a more streamlined operation.

**Tip:** Consider conducting a cost-benefit analysis to determine the potential savings in labor costs when integrating a case packer into your brewery.

Moreover, by minimizing the need for manual labor, case packers help reduce labor costs, which can be a substantial part of operational expenses in a brewery. Automation takes over repetitive packing tasks, leading to fewer workplace injuries and lower employee turnover. This shift towards mechanization means that breweries can allocate their human resources to more skilled and valuable functions, enhancing overall productivity.

**Tip:** Regular maintenance of your case packing equipment is crucial to ensure its efficiency and longevity, which can further contribute to cost savings.

Adopting a case packer is not just about packing efficiency; it’s about embracing a system that supports growth and sustainability in the ever-evolving brewing industry.

Maintaining Quality Control with Automated Packaging Solutions

In the competitive landscape of the brewing industry, maintaining quality control is paramount, especially during the packaging process. Automated packaging solutions, such as case packers, play a crucial role in ensuring that every product meets the brewery’s high standards. By minimizing human error and variability, these machines provide a consistent packaging experience, which is essential for preserving the integrity of the beer. This consistency not only safeguards the flavor and freshness but also enhances the brand's reputation among consumers.

Furthermore, automated packaging systems streamline production workflows, allowing breweries to focus on quality over quantity. With the ability to manage multiple packaging formats, case packers adapt easily to various product lines while maintaining rigorous checks during the process. This adaptability ensures that each batch is packaged quickly and accurately, reducing waste and potential recalls. By investing in automated solutions, breweries can enhance their efficiency and profitability while reinforcing their commitment to quality control, ultimately leading to greater customer satisfaction and loyalty.

Case Packer Selection Criteria for Breweries: What to Consider

When selecting a case packer for your brewery, several criteria should be prioritized to ensure efficiency and profitability. First, consider the production capacity of the packer in relation to your brewery's output. A case packer should be able to accommodate your current needs while having the flexibility to scale with your growth. Look for machines that can handle various packaging sizes and formats to provide versatility.

Next, the ease of maintenance and operation is crucial. Opt for models that offer user-friendly controls and require minimal downtime for servicing. This translates into a smoother operation process, keeping your production line running effectively.

Tips: When evaluating case packers, always ask for a demonstration to understand its functionality. Additionally, consider the manufacturer's support and service options — a reliable partner can make all the difference when issues arise. Lastly, ensure the case packer integrates seamlessly with your existing line, minimizing disruptions during the transition.

Related Posts

-

Innovations in Case Packer Machines: What Global Buyers Should Know for 2025

-

Innovative Designs of Best Carton Erector Machine for Global Buyers

-

12 Remarkable Benefits of Using a Case Packer Machine in Your Production Line

-

In Depth Comparison of Different Carton Erector Machines for Your Business Needs

-

7 Compelling Advantages of Investing in a Box Erector Machine for Your Business

-

The Future of Best Automatic Palletizer Machines Transforming Logistics Automation