The Future of Best Automatic Palletizer Machines Transforming Logistics Automation

As logistics automation continues to evolve, the spotlight is increasingly shining on the Automatic Palletizer Machine, a pivotal player in enhancing efficiency and productivity within manufacturing facilities globally. In recent years, the surge in demand for automated solutions has led to remarkable advancements in palletizing technology, enabling factories to streamline their operations and adapt to the dynamic needs of international markets. With leading manufacturers prioritizing automation to gain a competitive edge, the future of the Automatic Palletizer Machine promises not only to revolutionize how products are handled and stored but also to significantly reduce labor costs and errors. As we delve into the transformative potential of these machines, we will explore how they are setting the standard for logistics automation and positioning businesses to thrive in the increasingly interconnected global marketplace.

Understanding Automatic Palletizers: Key Features and Technologies

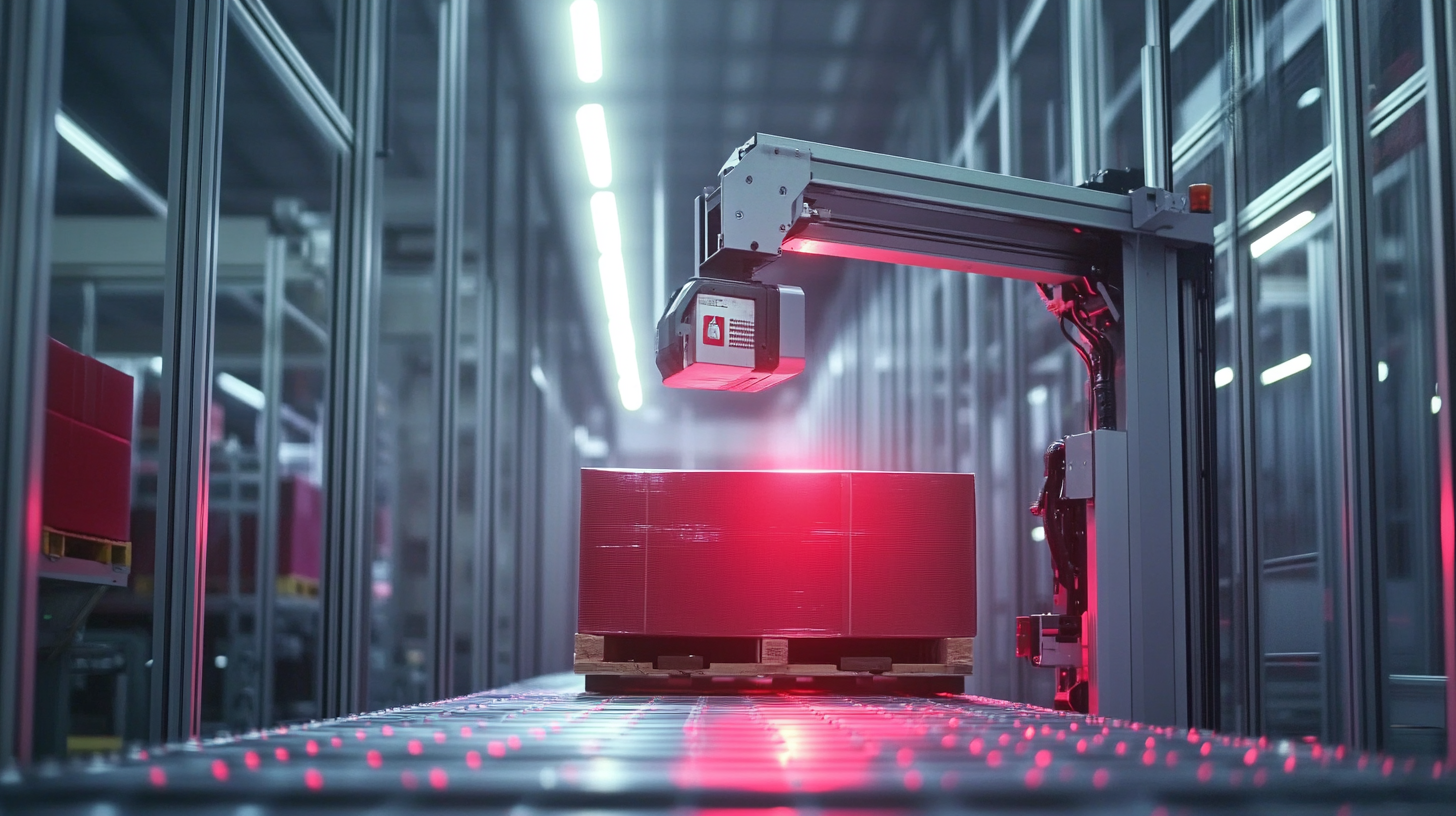

Automatic palletizers are revolutionizing the logistics industry by automating the stacking and organization of products onto pallets. These machines not only enhance efficiency but also reduce labor costs and minimize the risk of workplace injuries. Understanding the key features and technologies of automatic palletizers is essential for businesses looking to upgrade their operations.

One of the most critical features of modern automatic palletizers is their adaptability to various product types and sizes. This flexibility allows them to cater to diverse industry needs, from food and beverage to pharmaceuticals. Additionally, advanced technologies such as vision systems enable precise alignment and placement, ensuring that products are stacked securely and consistently.

Tip: When selecting a palletizer, consider a model that offers easy integration with existing production lines. This will not only streamline operations but also maximize your return on investment. Furthermore, look for machines equipped with adjustable frameworks, allowing for quick modifications that accommodate different products as your inventory changes.

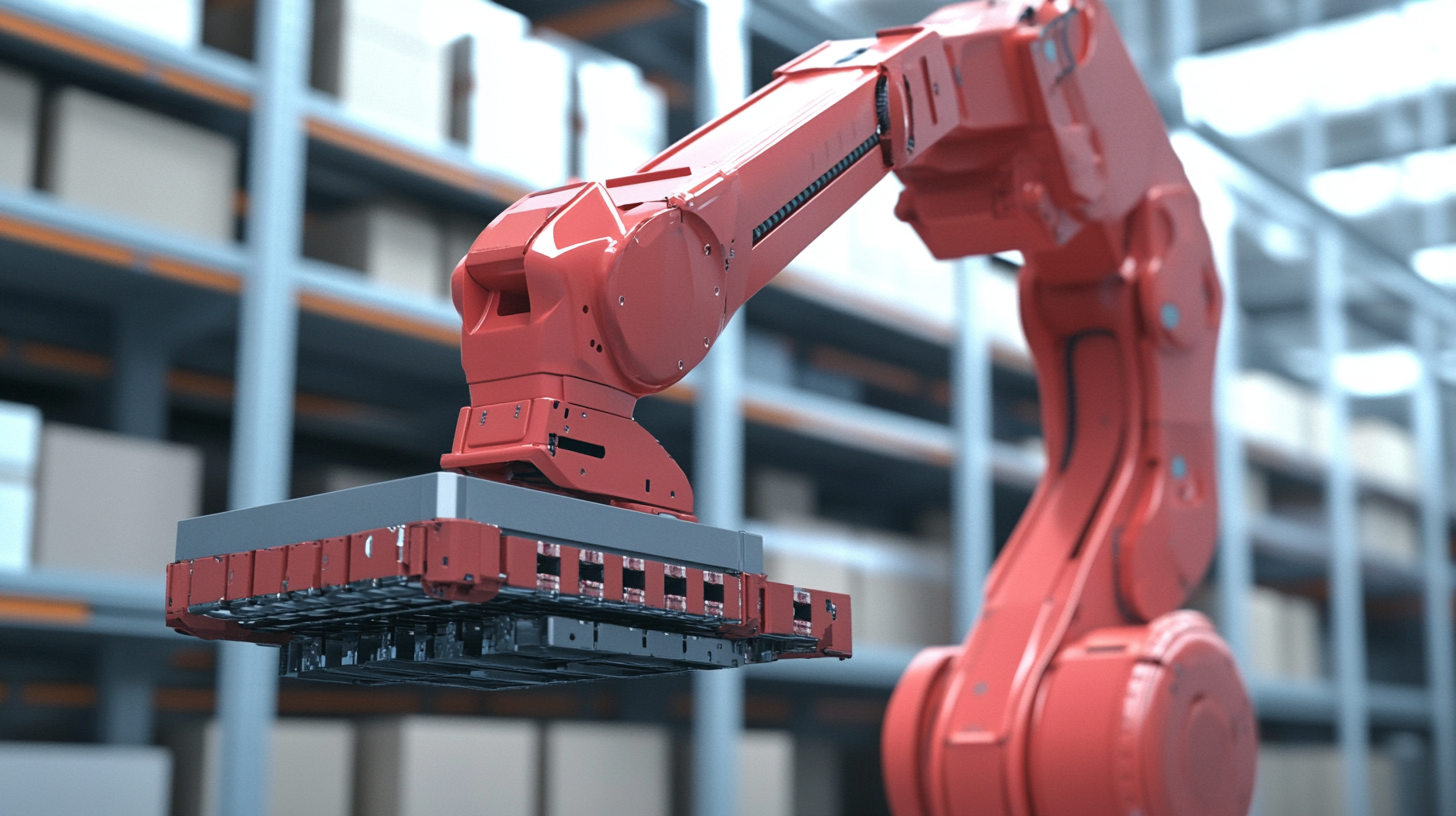

Another important technology is the use of robotics in palletizing systems. Robotic palletizers can handle delicate items with care while maintaining high-speed productivity. Their ability to learn and adapt through machine learning enhances their efficiency over time.

Tip: Ensure the robotic system features an intuitive user interface for easier training of staff and regular updates. Investing in a user-friendly system will facilitate faster adaptation and less downtime, ultimately improving overall productivity in your warehouse.

Top Benefits of Implementing Automatic Palletizing Systems in Logistics

The implementation of automatic palletizing systems in logistics offers numerous advantages that can significantly enhance operational efficiency. One of the primary benefits is the reduction of labor costs. By automating the palletizing process, companies can minimize the number of workers needed for repetitive tasks, allowing for reallocation of human resources to more strategic areas of the business. This not only improves workforce productivity but also reduces the risk of workplace injuries associated with manual handling.

Moreover, automatic palletizers increase the speed and accuracy of the palletizing process. These machines are designed to handle bulk products swiftly, ensuring that items are stacked consistently and securely. This eliminates the variability that often comes with human labor, leading to a more reliable supply chain. Additionally, the integration of advanced technology in palletizing systems allows for real-time monitoring and data collection, enabling businesses to optimize their operations and respond quickly to changing demands in the logistics landscape. Overall, investing in automatic palletizing systems paves the way for a more streamlined and efficient logistics operation.

A Comparison of Leading Automatic Palletizer Machines on the Market

Automatic palletizers are at the forefront of logistics automation, playing a crucial role in enhancing productivity and efficiency in warehouses and distribution centers. As industries increasingly adopt automated solutions, comparing leading automatic palletizer machines reveals significant advancements in technology and design. Modern palletizers are equipped with intelligent systems that enable precise handling of various products, from boxes to irregular shapes, thereby minimizing human error and optimizing workflow. These innovations not only streamline operations but also contribute to a safer working environment by reducing the physical strain on employees.

The market for collaborative robots is experiencing exponential growth, with a projected shift from USD 1.36 billion in 2021 to over USD 16.39 billion by 2028. This explosion in investment highlights the demand for versatile automation solutions that can seamlessly integrate into existing systems. Companies are introducing sophisticated models with enhanced payload capacities and extended reach, catering to specific applications such as palletizing and packaging. As industries continue to navigate the complexities of logistics automation, the competition among leading manufacturers remains fierce, pushing the boundaries of what's possible in efficient and effective palletizing solutions.

Future Trends in Logistics Automation: The Role of Palletizers

The logistics automation industry is undergoing a remarkable transformation, and palletizers are at the forefront of this evolution. In 2022, the global market for palletizing equipment was valued at approximately $3.4 billion, with projections indicating it will reach $5.5 billion by 2030, growing at a CAGR of 6.0% (Source: Logistics Automation Report 2023). This growth highlights the increasing reliance on automated solutions to enhance efficiency and productivity in supply chain operations. Palletizers, capable of swiftly organizing goods onto pallets, are essential in streamlining processes and reducing human error.

To leverage the advantages of palletizers effectively, companies should consider several tips. First, it's crucial to assess the specific needs of your operation; this includes understanding the types of products to be palletized and the space available. Investing in a modular system can allow for easier adjustments as business needs evolve. Second, regular maintenance is key to ensuring optimal performance and minimizing downtime. Research shows that facilities with preventive maintenance schedules can reduce equipment failure rates by up to 30% (Source: Maintenance Best Practices Report 2023).

As companies integrate smart technologies into their processes, palletizers equipped with AI and machine learning will play an increasingly pivotal role. These advanced systems not only enhance speed and accuracy but also gather valuable data analytics to drive future decision-making. The logistics industry is on a path to embrace these innovations, and those who adapt will lead the charge in efficiency.

The Future of Best Automatic Palletizer Machines Transforming Logistics Automation

| Feature | Current Trends | Future Predictions | Impact on Logistics |

|---|---|---|---|

| Flexibility | High adaptability to different products | Increased modular designs | Improved efficiency in diverse operations |

| Integration with AI | Basic automation with AI features | Full-scale AI integration | Enhanced decision-making and predictive capabilities |

| Speed | Current systems achieving up to 120 cycles per minute | Potential to reach 200+ cycles per minute | Significantly reduced throughput times |

| Data Analytics | Basic reporting features included | Advanced analytics capabilities | Better optimization of logistics processes |

| Sustainability | Initial focus on energy-efficient machines | Complete eco-friendly solutions | Reduction in carbon footprint of logistics |

Real-World Applications: Success Stories of Automatic Palletizer Integration

In recent years, automatic palletizer machines have become pivotal in transforming logistics automation. Their integration into warehouse operations not only boosts efficiency but also enhances accuracy. A report by Research and Markets indicates that the palletizing automation market is projected to reach $3.4 billion by 2025, growing at a CAGR of 6.2%. This growth reflects the increasing demand for enhanced operational efficiency in supply chains, especially in industries like food & beverage, pharmaceuticals, and consumer goods.

Real-world applications highlight the tangible benefits of adopting automatic palletizers. For example, a case study from a leading beverage distributor reported a 30% increase in productivity after implementing automatic palletization systems. The company was able to reduce manual handling, streamline operations, and minimize errors, resulting in significant cost savings. Similarly, a pharmaceutical manufacturer leveraged automatic palletizers to maintain compliance and increase throughput, achieving compliance rates of over 99% in their packaging processes. These success stories illustrate not only the ROI but also the critical role of technology in adapting to the evolving logistics landscape.