Exploring Innovative Alternatives to Automatic Box Tapers for Efficient Packaging Solutions

In recent years, the packaging industry has witnessed a significant transformation driven by technological advancements and evolving consumer demands. According to a report by Smithers Pira, the global market for packaging machinery is projected to reach $54.4 billion by 2025, highlighting a growing need for efficient solutions. Among these, Automatic Box Tapers have long been a staple for streamlining the sealing process; however, their limitations in flexibility and adaptability have prompted the search for innovative alternatives. As companies strive to enhance operational efficiency and sustainability, exploring alternatives to Automatic Box Tapers has become crucial. This blog delves into various innovative packaging solutions that can outperform traditional methods, offering insights into how businesses can optimize their packaging processes while meeting the dynamic requirements of the market.

Innovative Robotics Trends in Packaging: Improving Efficiency and Reducing Error Rates

In the ever-evolving world of packaging, robotics have emerged as a game-changer, driving innovation and efficiency in an industry that demands precision and speed. Traditional packaging methods, such as automatic box tapers, often struggle with high error rates and inflexible processes. However, the latest trends in robotic automation offer advanced solutions that not only improve efficiency but also minimize the risk of errors throughout the packaging cycle. Robotic arms equipped with sophisticated sensors and AI algorithms can quickly adapt to different packaging sizes and shapes, optimizing both the time and resources needed to complete tasks.

Moreover, integrating robotics with smart technologies such as machine learning and IoT enables real-time data analysis, allowing for predictive maintenance and workflow optimization. This synergy not only streamlines operations but also enhances product quality by ensuring consistent packaging and reducing human intervention. As businesses seek to meet increasing consumer demands for speed and accuracy, investing in innovative robotic solutions is becoming essential.

These advancements not only pave the way for reduced operational costs but also contribute to a more sustainable and responsive packaging ecosystem.

The Cost-Benefit Analysis of Alternatives to Automatic Box Tapers in Packaging Operations

In today’s rapidly evolving packaging industry, businesses are continuously seeking efficient solutions that balance performance and cost. The cost-benefit analysis of alternatives to automatic box tapers reveals that while these machines offer speed, there are innovative options that may better serve specific operational needs.

Manual taping machines, for instance, generally require a lower initial investment and provide flexibility for smaller production runs. This allows companies to minimize overhead while maintaining a personalized touch in their packaging processes.

Manual taping machines, for instance, generally require a lower initial investment and provide flexibility for smaller production runs. This allows companies to minimize overhead while maintaining a personalized touch in their packaging processes.

When considering alternatives, it's essential to evaluate not only the upfront costs but also the long-term implications on labor and efficiency. Automated packing stations, which combine labeling and sealing in one unit, could reduce workforce reliance and increase throughput significantly. However, the total cost of ownership should factor in maintenance, training, and overall workflow integration.

Tip 1: Analyze your production volume to choose the right solution; low-volume operations may benefit from manual options, while high-volume needs might justify an investment in automation.

Tip 2: Consider hybrid solutions that incorporate both manual and automatic systems to enhance flexibility and efficiency without sacrificing budget constraints.

Sustainability in Packaging: Eco-Friendly Solutions Beyond Traditional Box Taping Methods

In today’s packaging industry, the call for sustainability is louder than ever. As businesses seek to reduce their environmental impact, innovative alternatives to traditional box taping methods are being explored. Companies are now turning to solutions like compostable adhesive tapes, biodegradable materials, and even plant-based sealants that optimize efficiency while minimizing waste. These advanced options not only maintain the integrity of packaging but also promote a greener future.

**Tip: Evaluate Eco-Friendly Materials**

When selecting packaging materials, always look for certifications that ensure sustainability, such as FSC (Forest Stewardship Council) or biodegradable labels. This ensures that your packaging choices contribute positively to the environment.

Another exciting development is the use of water-activated tapes that bond securely without damaging the cardboard, making them easier to recycle. This type of tape reduces plastic usage and is an excellent alternative for those looking to streamline their packaging process sustainably.

**Tip: Reassess Your Taping Technique**

Consider implementing new techniques such as “taping by hand” with eco-friendly adhesives to cut down on machinery and energy usage. This method not only saves energy but can also allow for more precision in packaging, reducing material waste.

Exploring Innovative Alternatives to Automatic Box Tapers for Efficient Packaging Solutions

| Alternative Method | Material Used | Efficiency Rating | Sustainability Score | Cost Comparison (%) |

|---|---|---|---|---|

| Biodegradable Adhesives | Plant-Based Polymers | 8/10 | 9/10 | 10% Lower |

| Reusable Clamps | Aluminum and Plastic | 9/10 | 8/10 | 15% Higher |

| Biobased Stretch Film | Polyethylene derived from Sugarcane | 7/10 | 9/10 | 5% Higher |

| Water-Soluble Packaging | PVA (Polyvinyl Alcohol) | 10/10 | 10/10 | 20% Lower |

| Eco-Friendly Tape | Recycled Paper | 8/10 | 8/10 | 5% Lower |

Case Studies: Companies Successfully Implementing Alternative Packaging Solutions

In the pursuit of efficient packaging solutions, companies are increasingly turning to innovative alternatives to traditional automatic box tapers. One noteworthy case study comes from a mid-sized e-commerce firm that replaced its automatic taping machines with a manual adhesive taping process complemented by custom-designed packaging. This approach not only reduced material costs but also allowed for greater flexibility in packaging various product sizes, leading to improved customer satisfaction. By involving employees in the packaging process, the company fostered a sense of ownership that boosted morale and productivity.

Another compelling example is a global consumer goods manufacturer that implemented a fully automated packaging line utilizing eco-friendly materials. By adopting a plant-based adhesive system and biodegradable tapes, the company not only streamlined its operations but also resonated with environmentally conscious consumers. The transition resulted in a 30% reduction in waste and significantly enhanced the brand's reputation in sustainability. These case studies illustrate that rethinking packaging strategies can not only optimize efficiency but also align with market trends and consumer preferences.

Innovative Alternatives to Automatic Box Tapers in Packaging Solutions

This chart illustrates the efficiency of various innovative packaging solutions compared to traditional automatic box tapers. The data represents the percentage of operational efficiency and material usage across different alternative methods.

Future of Packaging Automation: Predictions and Emerging Technologies Transforming the Industry

The packaging industry is on the brink of a transformative evolution, powered by advancements in automation and artificial intelligence. As we look toward 2025 and beyond, the market for robotics in industrial automation is projected to experience substantial growth, with a compound annual growth rate (CAGR) of 30%. This surge is largely driven by the increasing adoption of collaborative and humanoid robots, which enhance efficiency and flexibility in packaging solutions.

Emerging technologies are poised to redefine traditional packaging methods. For instance, artificial intelligence is being integrated into supply chain processes, enabling predictive analytics that streamline operations and reduce waste. Additionally, advancements in advanced computing are paving the way for real-time data processing, allowing businesses to react swiftly to market changes. These innovations not only optimize production lines but also enable companies to meet the growing demand for sustainable and customized packaging solutions.

As we explore the future landscape of packaging automation, it's crucial to acknowledge that the integration of these technologies will be key to staying competitive. The next few years will undoubtedly shape the industry's trajectory, laying the groundwork for smarter, more efficient packaging solutions that are responsive to the evolving needs of consumers and businesses alike.

Related Posts

-

Maximizing Efficiency in Automated Packaging Systems with Cost Effective Maintenance Solutions

-

How to Choose the Best Packaging Machinery for Your Business Needs

-

7 Benefits of Choosing Packaging Robots for Your Business Efficiency

-

Finding Reliable Suppliers for Your Box Taping Machine with Effective Approaches

-

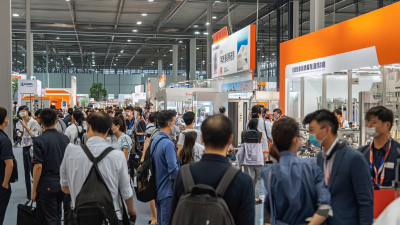

Maximizing Your Export Potential with Carton Taping Machines at the 2025 Canton Fair

-

Discovering Innovative Alternatives to the Best Automatic Case Sealer for Your Packaging Needs