A Comprehensive Guide to Maximizing Efficiency with Box Erectors in Modern Manufacturing

In today's fast-paced manufacturing environment, the importance of efficiency cannot be overstated, and the integration of Box Erectors is revolutionizing the packaging process. According to a recent report by MarketsandMarkets, the global box erecting machine market is projected to reach $1.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.6%. This surge in demand underscores the necessity for manufacturers to adopt innovative solutions that streamline operations while minimizing labor and material costs.

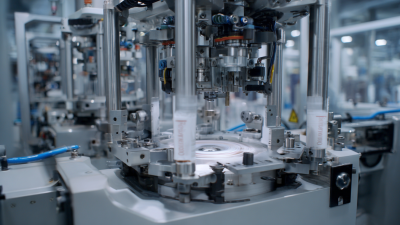

Box Erectors not only automate the assembly of cardboard boxes but also significantly reduce the time required for packaging, leading to enhanced productivity on the factory floor. As companies continue to seek ways to modernize their processes, understanding the full potential of Box Erectors becomes essential for maintaining a competitive edge in the industry.

Understanding Box Erectors: Types and Their Roles in Modern Manufacturing

Box erectors play a pivotal role in the landscape of modern manufacturing, especially as businesses strive for enhanced operational efficiency. These machines, designed for the automatic assembly of cardboard boxes, can significantly reduce labor costs and time, enabling manufacturers to focus on other critical areas. According to a report by The Freedonia Group, the demand for box erectors is expected to grow at a compound annual growth rate (CAGR) of 4.7% through 2025. This reflects the growing need for automation in packaging processes as a response to increasing e-commerce and consumer demands for quick turnaround times.

There are various types of box erectors, each tailored for specific manufacturing environments. For instance, semi-automatic box erectors are ideal for small to medium-sized operations, while fully automatic models are suited for high-volume production lines. A study by the Packaging Machinery Manufacturers Institute (PMMI) indicates that companies utilizing fully automatic box erectors can increase their packaging throughput by over 30%, significantly bolstering overall productivity. The versatility and efficiency of modern box erectors make them indispensable in streamlining production processes and meeting the changing demands of the market.

Key Benefits of Implementing Box Erectors for Operational Efficiency

In today's fast-paced manufacturing environment, operational efficiency is a critical driver of success. Implementing box erectors can significantly enhance this efficiency by streamlining the packing process. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), automating box forming can reduce the time required for packaging tasks by up to 50%. This not only speeds up production lines but also allows employees to focus on more value-added activities, ultimately increasing overall output.

Moreover, the reliability of box erectors contributes to lower operational costs. A study published by the Association for Packaging and Processing Technologies highlights that using automated box erecting systems can lead to a reduction in material waste by approximately 20%. This improvement not only cuts costs but also aligns with sustainability goals, as manufacturers are increasingly pressured to minimize their environmental impact. By leveraging the capabilities of box erectors, manufacturers can optimize their operations, reduce labor costs, and enhance their competitiveness in the market.

Integrating Technology: How Automation Enhances Box Erector Performance

In the realm of modern manufacturing, the integration of technology has revolutionized the performance of box erectors, making them indispensable for enhancing operational efficiency. According to a recent report by the Association for Packaging and Processing Technologies, companies utilizing automated box erectors have seen productivity improvements of up to 40%, drastically reducing the time taken for packaging processes. These systems not only streamline the erection of boxes but also minimize labor costs and the likelihood of human errors, which can lead to product damage or rework.

Moreover, advancements in automation technology, such as smart sensors and machine learning algorithms, have enabled box erectors to adapt to fluctuating production demands with unparalleled precision. The Packaging Machinery Manufacturers Institute reports that firms employing automated solutions experience a 30% reduction in waste material, as these machines optimize the use of resources more effectively than manual operations. Embracing automation in box erecting processes not only enhances efficiency but also leads to significant cost savings, positioning manufacturers for greater success in an increasingly competitive market.

A Comprehensive Guide to Maximizing Efficiency with Box Erectors in Modern Manufacturing - Integrating Technology: How Automation Enhances Box Erector Performance

| Feature | Benefits | Impact on Efficiency | Automation Level | Example Use Case |

|---|---|---|---|---|

| Speed Adjustment | Allows for fine-tuning based on production needs | Increases output per hour | High | E-commerce packaging lines |

| Material Compatibility | Handles various box sizes and materials | Reduces downtime for changeovers | Medium | Food packaging and distribution |

| Integration with ERP Systems | Streamlines operations across departments | Enhances workflow and reduces errors | High | Manufacturing resource planning |

| User-Friendly Interface | Easy for operators to learn and use | Increases operator productivity | Medium | Consumer goods assembly lines |

| Predictive Maintenance | Reduces unexpected downtime | Maintains production flow | High | Automotive parts manufacturing |

Best Practices for Maintenance and Optimization of Box Erectors

Maintaining box erectors in modern manufacturing is essential for maximizing efficiency and minimizing downtime. Regular maintenance practices such as routine inspections, lubrication of moving parts, and thorough cleaning can significantly extend the lifespan of these machines. Implementing a preventive maintenance schedule not only helps in identifying wear and tear early but also reduces the chances of unexpected breakdowns, thereby ensuring seamless production flow.

Optimization of box erectors involves fine-tuning their operational settings to meet specific production requirements. This can include adjusting machine speed, calibration of sensors, and enhancing software controls to ensure precision in box formation. Additionally, training staff on best practices for machine operation and troubleshooting can lead to improved performance and quicker resolution of issues. By prioritizing both maintenance and optimization strategies, manufacturers can achieve significant gains in productivity, ultimately driving a more efficient production process.

A Comprehensive Guide to Maximizing Efficiency with Box Erectors in Modern Manufacturing

Future Trends: Innovations in Box Erectors for Enhanced Manufacturing Efficiency

The landscape of manufacturing is rapidly evolving, and box erectors are at the forefront of this transformation. As companies strive for enhanced efficiency, innovations in box erector technology are emerging to meet the demands of modern production. One significant trend is the integration of smart technology, allowing for real-time monitoring and adjustments. These intelligent systems can analyze performance data, reduce waste, and optimize the speed of box formation, ultimately leading to increased operational efficiency.

Additionally, sustainability is becoming a key focus, with many manufacturers seeking eco-friendly solutions. Innovations such as biodegradable materials or energy-efficient machinery are being implemented to minimize the environmental impact of packing processes. Furthermore, advancements in automation, including robotics and AI, are streamlining operations, allowing for greater precision and speed in the erectors' functioning. As these technologies continue to develop, manufacturers are positioned to not only meet current market demands but also anticipate future challenges, ensuring their operations remain competitive in a dynamic industrial environment.

Related Posts

-

Navigating Global Trade Challenges with the Best Box Taping Machine from China

-

Optimize Your Packaging Line with High Efficiency Carton Taping Machines

-

Unmatched Quality: China's Leading Exporter of Premier Palletizing Systems

-

The Future of Best Packaging Machinery: Innovations Shaping Tomorrow's Industry

-

How to Identify Reliable Suppliers for the Best Case Sealer Without Compromise

-

Discover Top Quality Carton Erector Machines from Leading Chinese Manufacturers