Why Packaging Equipment is Essential for Efficient Production Processes

The importance of Packaging Equipment in modern manufacturing cannot be overstated, as it plays a critical role in driving efficiency and productivity across various industries. According to a report by Smithers Pira, the global market for packaging machinery is projected to reach approximately $50 billion by 2026, reflecting a compound annual growth rate (CAGR) of around 5.3%. This growth is primarily driven by the increasing demand for sustainable packaging solutions and the need for automation in production lines to reduce costs and enhance operational efficiencies.

Experts in the field emphasize the necessity of incorporating advanced Packaging Equipment to stay competitive in today's fast-paced market. Paul Robinson, a renowned packaging technology specialist, stated, “Investing in state-of-the-art Packaging Equipment not only streamlines production processes but also significantly reduces waste and improves product integrity.” Such insights highlight the critical connection between effective packaging strategies and overall production performance.

Moreover, as industries such as food and beverage, pharmaceuticals, and consumer goods evolve, the role of Packaging Equipment becomes even more essential. Manufacturers are increasingly looking for innovative solutions that can adapt to changing consumer preferences while ensuring compliance with stringent quality standards. In this context, understanding the significance of Packaging Equipment is vital for businesses aspiring to optimize their production processes and achieve long-term growth.

Importance of Packaging Equipment in Modern Manufacturing

In the dynamic landscape of modern manufacturing, packaging equipment plays a pivotal role in enhancing production efficiency. As industries embrace automated solutions, the need for reliable and advanced packaging machinery has become paramount. This equipment not only streamlines the packaging process but also significantly reduces the labor required, allowing for faster turnaround times and increased output. By minimizing manual handling and potential errors, manufacturers can ensure higher consistency and quality in their packaged products.

Moreover, the right packaging equipment is essential for adapting to changing market demands. With the rise of e-commerce and consumer expectations for quick delivery, manufacturers need to be agile in their packaging processes. High-speed machines can accommodate various product sizes and types, making it easier to switch production lines quickly. This flexibility is vital for companies aiming to stay competitive in an ever-evolving marketplace. Ultimately, the investment in modern packaging technology is not just about improving workflow; it is about aligning production capabilities with industry trends and consumer needs.

Types of Packaging Equipment and Their Functions

When considering the types of packaging equipment, it’s important to recognize how each piece plays a vital role in enhancing production efficiency. Filling machines, for instance, are designed to precisely dispense liquids or solids into containers, reducing waste and ensuring uniformity. Sealing machines follow suit by securing packages to maintain product integrity, while labeling machines add essential branding and information that guide consumers. Each of these tools works in harmony to streamline operations and minimize human error.

Tips: Regularly maintain your packaging equipment to avoid costly downtime. Check for any wear and tear that could affect performance and implement a routine cleaning schedule to ensure optimal operation.

Another crucial category is the case packing machinery, which automates the process of packing products into boxes, increasing speed and consistency. Stretch wrappers also play a significant role by securing products on pallets, protecting them during storage and transit. Investing in the right combination of packaging equipment not only speeds up production but also enhances safety and reliability within the supply chain.

Tips: Consider the specific needs of your production line when choosing equipment. Customizing your packaging solutions can lead to improved efficiency and better product protection during distribution.

How Packaging Equipment Enhances Production Efficiency

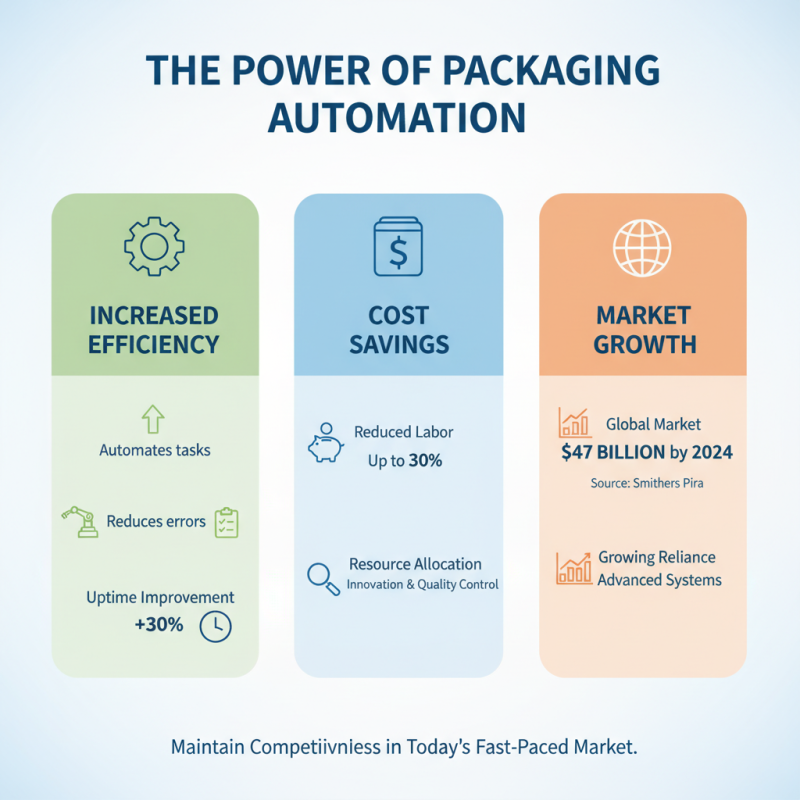

Efficient production processes are vital for maintaining competitiveness in today’s fast-paced market. Packaging equipment plays a crucial role in enhancing production efficiency by automating packaging tasks and reducing the likelihood of errors. According to a report by Smithers Pira, the global packaging machinery market is set to grow to $47 billion by 2024, reflecting the growing reliance on advanced packaging systems. Automation reduces labor costs by up to 30%, enabling manufacturers to allocate resources more effectively towards innovation and quality control.

Moreover, modern packaging equipment incorporates smart technology that optimizes speed and accuracy, resulting in higher output. A study by PMMI (The Association for Packaging and Processing Technologies) reveals that manufacturers using automated packaging solutions see efficiency improvements of approximately 20-50%, significantly decreasing time-to-market. This technological integration allows for real-time monitoring and adjustments during production, ensuring that packaging meets exact specifications and enhances overall product quality. Ultimately, investing in advanced packaging equipment is not merely an operational choice; it is an essential strategy for achieving streamlined production processes and scalable growth in an increasingly competitive landscape.

Impact of Packaging Equipment on Product Quality and Safety

Packaging equipment plays a crucial role in maintaining product quality and safety across various industries. A recent report by the Food and Drug Administration (FDA) highlights that improper packaging can lead to significant losses, both financially and in terms of consumer trust.

According to the United Nations' Food and Agriculture Organization, about 1.3 billion tons of food is wasted every year due to inadequate packaging, emphasizing the importance of investing in proper packaging solutions.

Efficient packaging not only preserves the integrity of the product but also extends shelf life and ensures compliance with safety regulations.

Incorporating advanced packaging technologies can greatly enhance product safety. For instance, automated packaging systems minimize human error, reducing the risk of contamination and ensuring that products are sealed effectively.

A study published in the Journal of Packaging Technology and Research found that 70% of consumers consider packaging a key factor in determining product safety, further underlining the necessity for high-quality packaging equipment.

Tips: When selecting packaging equipment, consider the materials used, as they can significantly impact both quality and safety.

It's also beneficial to invest in equipment that allows for traceability, as this can help quickly identify issues related to product recalls or contamination.

Regular maintenance and training for staff on proper packaging techniques are essential for minimizing risks and maintaining high standards.

Trends and Innovations in Packaging Equipment Technologies

The field of packaging equipment technologies is evolving rapidly, driven by the need for greater efficiency, sustainability, and adaptability in production processes. One prominent trend is the integration of automation and robotics into packaging lines. These innovations allow for faster, more precise operations, reducing labor costs and minimizing human error. Automated systems can be programmed to handle different packaging formats, making them highly flexible and suitable for businesses that handle diverse product ranges.

Additionally, advancements in materials science have led to the development of smarter packaging solutions. Biodegradable and recyclable materials are increasingly being adopted, aligning with the global push towards sustainability. These new materials not only reduce environmental impact but also enhance product shelf life through better barrier properties. Another innovation involves the use of IoT (Internet of Things) technology in packaging machinery, which enables real-time monitoring and data analysis. This connectivity allows manufacturers to optimize their processes, predict maintenance needs, and ensure the highest standards of quality control throughout the production cycle.

Related Posts

-

Maximizing Efficiency in Automated Packaging Systems with Cost Effective Maintenance Solutions

-

Discovering Innovative Alternatives to the Best Automatic Case Sealer for Your Packaging Needs

-

Ultimate Guide to Choosing the Best Automated Packaging Solutions for Your Business Needs

-

Adhering to Industry Standards: How to Choose the Best Automatic Case Sealer for Optimal Efficiency

-

Ultimate Checklist for Choosing the Right Automatic Box Taping Machine

-

Understanding the Benefits of Automatic Palletizer Machines for Your Production Line