What is a Palletizer Machine and How Does It Work?

In today's fast-paced manufacturing world, the efficiency of a production line is crucial. One key player in this process is the Palletizer Machine. According to John Smith, a leading expert in warehouse automation, "A Palletizer Machine can significantly enhance productivity and accuracy in packaging.” This technology is reshaping how businesses handle their products.

Palletizer Machines automate the stacking of products onto pallets, saving time and reducing labor costs. Industries like food and beverage, pharmaceuticals, and consumer goods rely on them heavily. However, not all companies utilize them effectively. Some struggle with integration, facing challenges in aligning the machine with existing workflows.

The operation of a Palletizer Machine involves several processes, including product identification and stacking patterns. Understanding these processes can lead to better outcomes. Companies must assess their needs and choose the right palletizer to fit their specific operations. Despite their benefits, there are still pitfalls to avoid. Companies need to reflect on their choices and ensure continuous improvement in their palletizing systems.

What is a Palletizer Machine: Definition and Overview

A palletizer machine is a crucial tool in modern manufacturing. Its primary function is to automate the process of stacking products onto pallets for shipping. This automation enhances efficiency and reduces manual labor. Industry reports indicate that the palletizer market is expected to grow by 5.2% annually, reflecting the increasing demand for automation in warehouses.

Palletizers come in various types, including robotic and conventional systems. Robotic palletizers offer flexibility and precision. They adapt quickly to different product sizes and shapes. Conventional palletizers can handle high volumes efficiently. This choice often depends on the production needs of a facility. However, the initial investment can be substantial. Companies must weigh long-term savings against upfront costs.

Tip: Assess your production volume before selecting a palletizer. High-volume operations can benefit from high-speed models. Yet, flexibility may be more critical for businesses with diverse product lines. Always consult with a professional to ensure the right fit for your needs. Investing in the wrong type can lead to inefficiencies and higher operational costs. Remember, an effective palletizer can streamline processes but requires careful consideration.

Key Components of a Palletizing System and Their Functions

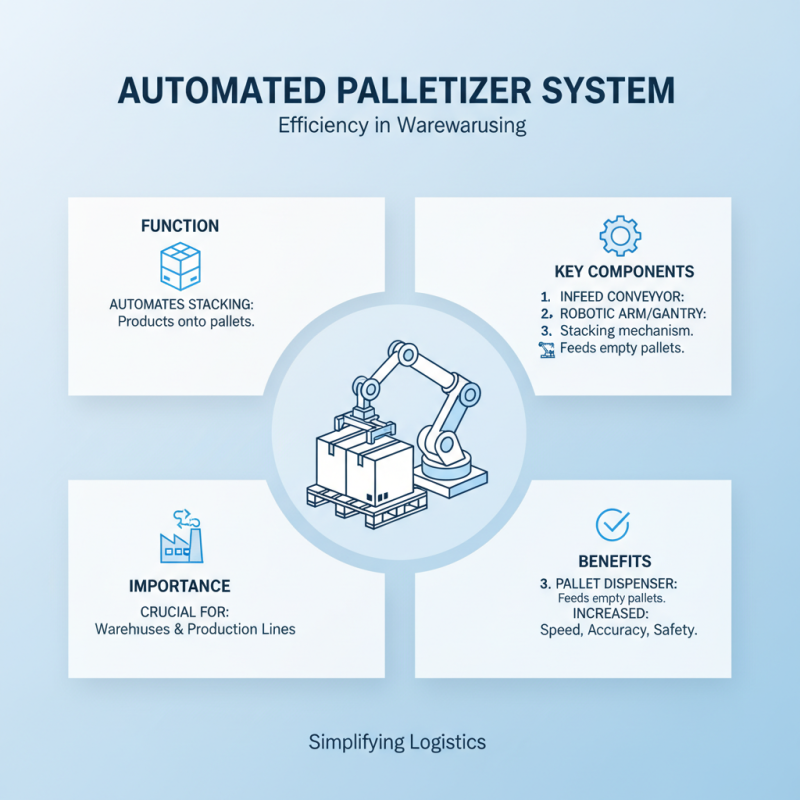

A palletizer machine automates the process of stacking products onto pallets. This system is crucial in warehouses and production lines. Understanding its key components helps in grasping how it operates effectively.

One essential part is the intake conveyor. It receives products from production lines. This conveyor must align items accurately. Misalignment can lead to bottlenecks. Another key component is the robotic arm or mechanical gripper. It picks items and places them precisely. The design of these arms varies greatly, allowing for different handling needs.

Control systems play a vital role as well. They manage the entire process using software. Sometimes, the system struggles with irregular-shaped items. This can slow down output rates. Operators must monitor performance and troubleshoot issues. With proper maintenance, a palletizing system can improve efficiency and reduce labor costs. The balance between automation and human oversight is essential.

Types of Palletizers: Robotic vs. Conventional (Case Studies)

Palletizers are essential in modern manufacturing. They automate the stacking of products onto pallets. There are two primary types: robotic and conventional palletizers. Each has its pros and cons, and the right choice depends on specific needs.

Robotic palletizers are flexible. They can handle various products and shapes. Their adaptability makes them ideal for different production lines. However, their initial cost can be high. Maintenance may also require skilled workers. This can be a drawback for smaller companies.

Conventional palletizers are more straightforward. They often have a lower initial investment. They excel in high-volume operations, making them a go-to for large-scale production. Yet, they may struggle with product variations. This rigidity can be limiting in dynamic environments.

Tips: Assess your production volume and product variety carefully. If your products change frequently, a robotic option may be wise. Conversely, if you have high, consistent demands, conventional might suffice. Always consider the total cost of ownership, not just initial costs. Evaluate your team's capacity for maintenance. A skilled workforce can maximize robotic systems effectively.

Palletizer Machine Usage by Type in Different Industries

Operational Process of a Palletizer Machine: Steps and Automation

The operational process of a palletizer machine is intricate yet fascinating. It automates the task of stacking products onto pallets. The machine typically includes a conveyor system, robotic arms, and sensors. Products arrive on a conveyor belt, where sensors identify their size and shape. This data guides the machine in arranging the items efficiently.

Once products are detected, the robotic arm engages. It picks up items and places them onto the pallet. This may happen in layers or columns, depending on the desired configuration. The quicker this process is executed, the more efficient the operation becomes. However, ensuring proper placement is crucial. Misalignment can lead to a domino effect, causing a cascade of issues down the line.

Tips for optimizing palletizer operations include regular maintenance checks. Routine inspections of the robotic arms and conveyor belts can prevent unexpected downtimes. Also, training staff to monitor the system enhances productivity. They can quickly resolve minor glitches before they escalate. Additionally, consider the layout of your workspace. A well-organized area fosters efficiency and reduces the risk of accidents.

Benefits of Palletizer Machines in Modern Manufacturing and Logistics

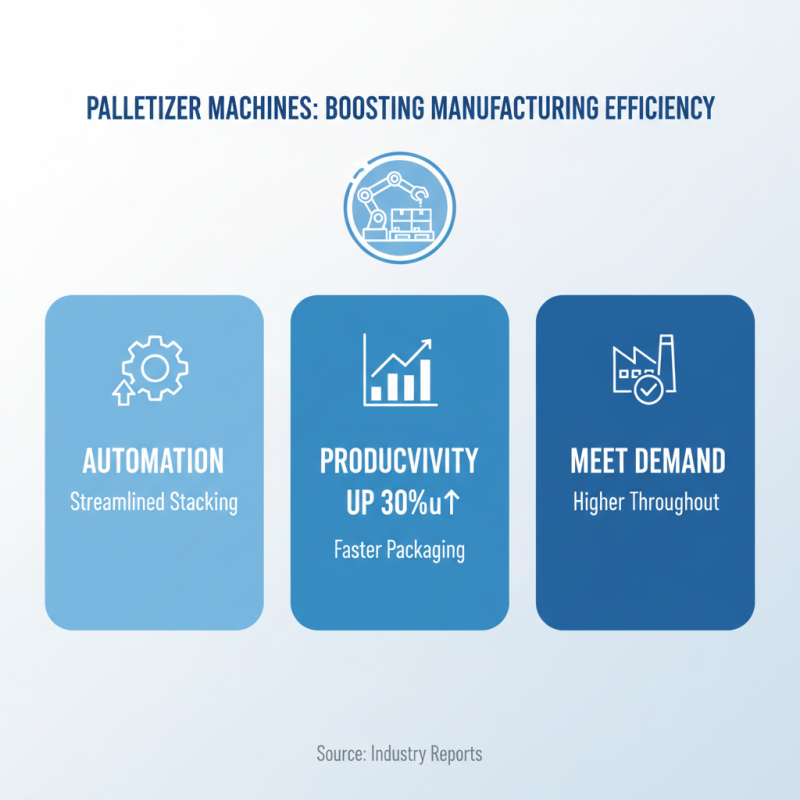

In the fast-evolving landscape of modern manufacturing and logistics, palletizer machines offer notable advantages. These machines streamline the packaging process by automating the stacking of products onto pallets. According to industry reports, the adoption of palletizing technology can boost productivity by up to 30%. This efficiency enables companies to meet rising consumer demands more effectively.

Palletizer machines minimize manual labor. By reducing human involvement in repetitive tasks, they enhance safety. A logistics study indicated that workplaces with automated palletizers saw a 25% reduction in accidents related to lifting. Despite these benefits, challenges remain. Some manufacturers may struggle with the initial costs of implementing these machines. Moreover, integrating palletizers with existing systems can complicate operations. Overall, the shift to automation is profound, yet not without its hurdles.

Related Posts

-

The Future of Best Automatic Palletizer Machines Transforming Logistics Automation

-

Understanding the Role of Palletizer Machines in Modern Manufacturing Efficiency

-

How to Choose the Right Palletizer Machine for Your Business Needs

-

Optimize Your Packaging Line with High Efficiency Carton Taping Machines

-

How to Select the Right Carton Taping Machine for Your Business Needs

-

Challenges Faced by Global Buyers When Selecting the Best Case Erector