Revolutionizing Logistics with Automated Palletizers at China Import and Export Fair 2025

As the world continues to embrace innovation, the logistics industry is undergoing a transformative shift with the introduction of Automated Palletizers, particularly showcased at the 2025 China Import and Export Fair (Canton Fair). This event, which marks its 138th session, serves as a pivotal platform for highlighting cutting-edge technologies that enhance supply chain efficiency.

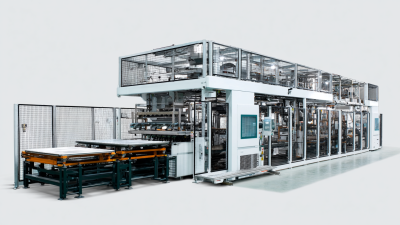

Automated Palletizers, designed to streamline the process of packing and sorting goods, offer unparalleled advantages in speed, accuracy, and labor reduction, positioning them as essential tools for modern logistics operations. With China's growing prominence in global trade, the integration of such advanced machinery not only boosts productivity but also aligns with the country's commitment to technological advancement and sustainability in manufacturing.

At the 2025 Fair, industry leaders and stakeholders will gather to explore the capabilities of Automated Palletizers, setting the stage for the future of logistics in an increasingly competitive landscape.

The Emergence of Automated Palletizers in the Logistics Industry

The logistics industry is on the brink of transformation with the rising use of automated palletizers, a trend highlighted at the China Import and Export Fair 2025. With the automated palletizer market estimated at $758.17 million and projected to reach $1.15333 billion by 2031, it is clear that these advanced machines are becoming an essential asset. These systems systematically stack goods or products onto pallets, significantly enhancing efficiency and reducing labor costs.

As businesses increasingly recognize the importance of automation, various trends are emerging within logistics. The acceleration of technological advancements, particularly in robotics, is expected to drive a compound annual growth rate of 4.77% in the automated palletizer sector. Companies looking to stay competitive should invest in innovative solutions that streamline their operations.

**Tip**: When considering an investment in automated palletizers, evaluate the specific needs of your operation to ensure that you choose machines that integrate seamlessly with your existing logistics framework. Implementing automation can lead to significant improvements in speed and accuracy.

Embracing these cutting-edge technologies not only positions companies for growth but also enhances their ability to adapt to the evolving demands of the global market.

Innovative Technologies Shaping the Future of Supply Chain Management

As we approach the China Import and Export Fair 2025, the spotlight turns to the innovative technologies transforming the supply chain landscape. Automation, particularly through automated palletizers, is revolutionizing logistics by streamlining processes and enhancing operational efficiency. This shift towards automated systems enables companies to tackle the complexities of modern supply chains while responding to the accelerating pace of global market dynamics.

AI-driven technologies are playing a pivotal role in this evolution. Advanced transportation management systems and warehouse robotics not only improve productivity but also reduce human error and operational costs. The integration of these technologies fosters a more sustainable and efficient supply chain ecosystem, demonstrating the impact of innovation on logistics and supply chain management.

**Tips:** To maximize efficiency in your supply chain, consider investing in automation tools that align with your operational needs. Additionally, staying abreast of technological trends can help identify new opportunities for improvement. Lastly, prioritize training for your team to seamlessly integrate these innovations into your existing processes, ensuring a smooth transition to a more automated workflow.

Efficiency Gains: How Automated Palletizers Streamline Operations

At the China Import and Export Fair 2025, the introduction of automated palletizers marks a significant leap forward in logistics efficiency. These cutting-edge machines utilize advanced robotics and AI technology to enhance the speed and accuracy of loading and unloading goods. By automating the palletizing process, companies can drastically reduce the time spent on manual labor, allowing for quicker response times to market demands.

The incorporation of automated palletizers leads to streamlined operations by minimizing human errors and optimizing workforce allocation. This technology not only increases throughput but also improves safety in the workplace by reducing the risks associated with heavy lifting and repetitive tasks. With real-time monitoring and data analytics capabilities, businesses can gain insights into their logistics processes, enabling them to continuously improve efficiency and adapt to changing operational needs. The shift towards automation at the fair showcases a transformative approach to modern logistics that is set to redefine industry standards.

Impact of Automation on Labor and Job Functions in Logistics

The adoption of automation in logistics, particularly with the introduction of automated palletizers, is reshaping job functions and labor dynamics within the sector. As reported, innovations in AI and automation are paving the way for what is labeled the Fourth Industrial Revolution. These technological advancements are projected to enhance productivity and operational efficiency, yet they also carry implications for the workforce. Research indicates that while automation might displace certain roles, it simultaneously creates new opportunities, often necessitating a shift in worker skill sets. A study highlighted that up to 85 million jobs could be displaced globally by 2025, while 97 million new roles may emerge that are more suited to the evolving labor market.

Collaborative AI technologies are expected to play a crucial role in the logistics sector by augmenting human capabilities rather than outright replacement. This collaborative approach can enhance job satisfaction, as workers equipped with the right training will be able to engage more effectively with automated systems. Furthermore, stakeholders across transport sectors have voiced the need for a balanced adaptation strategy embracing both automation and workforce development training, ensuring that workers can thrive alongside machines. According to recent findings, organizations that prioritize aligning technology with human resources see marked improvements in performance and employee engagement. This transition underscores the importance of preparing the workforce for a future where human-machine collaboration becomes the norm, reshaping how tasks are executed in logistics.

Showcasing Cutting-Edge Solutions at the China Import and Export Fair 2025

At the upcoming 2025 China Import and Export Fair, cutting-edge solutions will take center stage, particularly in the realm of logistics. The introduction of automated palletizers is set to revolutionize supply chain efficiency, marking a significant advancement in the industry. As companies increasingly turn to automation, these technologies promise not only to streamline operations but also to enhance productivity and reduce labor costs. This fair provides a unique platform for showcasing such innovations, inviting stakeholders to witness firsthand the impact of technology on logistics.

The fair will also highlight the importance of collaboration between various sectors, making it a pivotal event for those seeking to explore the intersection of technology and trade. As industries continue to innovate, showcasing these advancements at such a prominent event will facilitate valuable networking opportunities and foster international partnerships. Attendees can expect to engage with experts and gain insights into the future of automated solutions in logistics, further solidifying the fair's role as a hub for cutting-edge developments.

Revolutionizing Logistics with Automated Palletizers at China Import and Export Fair 2025

| Feature | Description | Benefits | Adoption Rate (%) |

|---|---|---|---|

| AI Integration | Utilizes artificial intelligence for optimized palletizing. | Improves efficiency and reduces operational costs. | 75% |

| Robust Design | Designed for durability and reliability in high-volume operations. | Lowers maintenance costs and increases uptime. | 80% |

| Flexible Configurations | Can be tailored to specific warehouse needs and layouts. | Enhances workspace efficiency and scalability. | 65% |

| Data Analytics | Incorporates data analytics for real-time performance monitoring. | Facilitates informed decision-making and continuous improvement. | 70% |

| Safety Features | Equipped with advanced safety systems to protect operators. | Minimizes accidents and promotes a safer work environment. | 85% |

Related Posts

-

The Ultimate Guide to Choosing the Best Automatic Palletizer Machine for Your Business Needs

-

Discovering Innovative Alternatives to the Best Automatic Case Sealer for Your Packaging Needs

-

Unmatched Quality: China's Leading Exporter of Premier Palletizing Systems

-

Adhering to Industry Standards: How to Choose the Best Automatic Case Sealer for Optimal Efficiency

-

Ultimate Checklist for Choosing the Right Automatic Box Taping Machine

-

Understanding the Benefits of Automatic Palletizer Machines for Your Production Line