Smart Automation for Global Packaging Solutions Quality You Can Trust

In today's fast-paced global market, the demand for quality packaging solutions has reached unprecedented levels. According to a report by Smithers Pira, the global packaging market is expected to grow to over $500 billion by 2024, driven largely by advancements in technology and automation. As businesses seek to enhance efficiency and maintain product integrity, Automated Packaging has emerged as a pivotal solution. This innovative approach not only streamlines production processes but also significantly reduces the risk of human error, ensuring that quality remains uncompromised. Additionally, a survey by the Association for Packaging and Processing Technologies revealed that 67% of companies using automated systems reported improvements in speed and consistency of their packaging operations. As we explore the intersection of automation and global packaging solutions, the focus on delivering quality you can trust has never been more crucial.

The Rise of Smart Automation in Packaging Industry

The packaging industry is experiencing a monumental shift with the rise of smart automation, as companies harness cutting-edge technologies to enhance efficiency and maintain quality. According to a recent report by Smithers Pira, the global smart packaging market is projected to reach $57 billion by 2027, demonstrating a growing interest in intelligent systems that streamline processes. Smart automation not only reduces operational costs but also improves production speed by up to 30%, allowing businesses to stay competitive in an ever-evolving market.

Incorporating smart automation into your packaging line can enhance accuracy and reduce error rates. For instance, predictive analytics help in anticipating equipment failures, leading to a reduction of downtime by approximately 15% (McKinsey & Company). Implementing integrated sensors and IoT devices can enable real-time monitoring, ensuring that products meet stringent quality standards throughout the packaging process.

**Tips:**

1. Start with automation assessment: Evaluate your current processes and identify areas where automation can yield the greatest benefits.

2. Invest in employee training: Equip your team with the necessary skills to operate and maintain advanced automated systems, fostering a culture of continuous improvement.

3. Choose scalable solutions: Select automation technologies that can adapt to your evolving needs, allowing you to grow without significant additional investments.

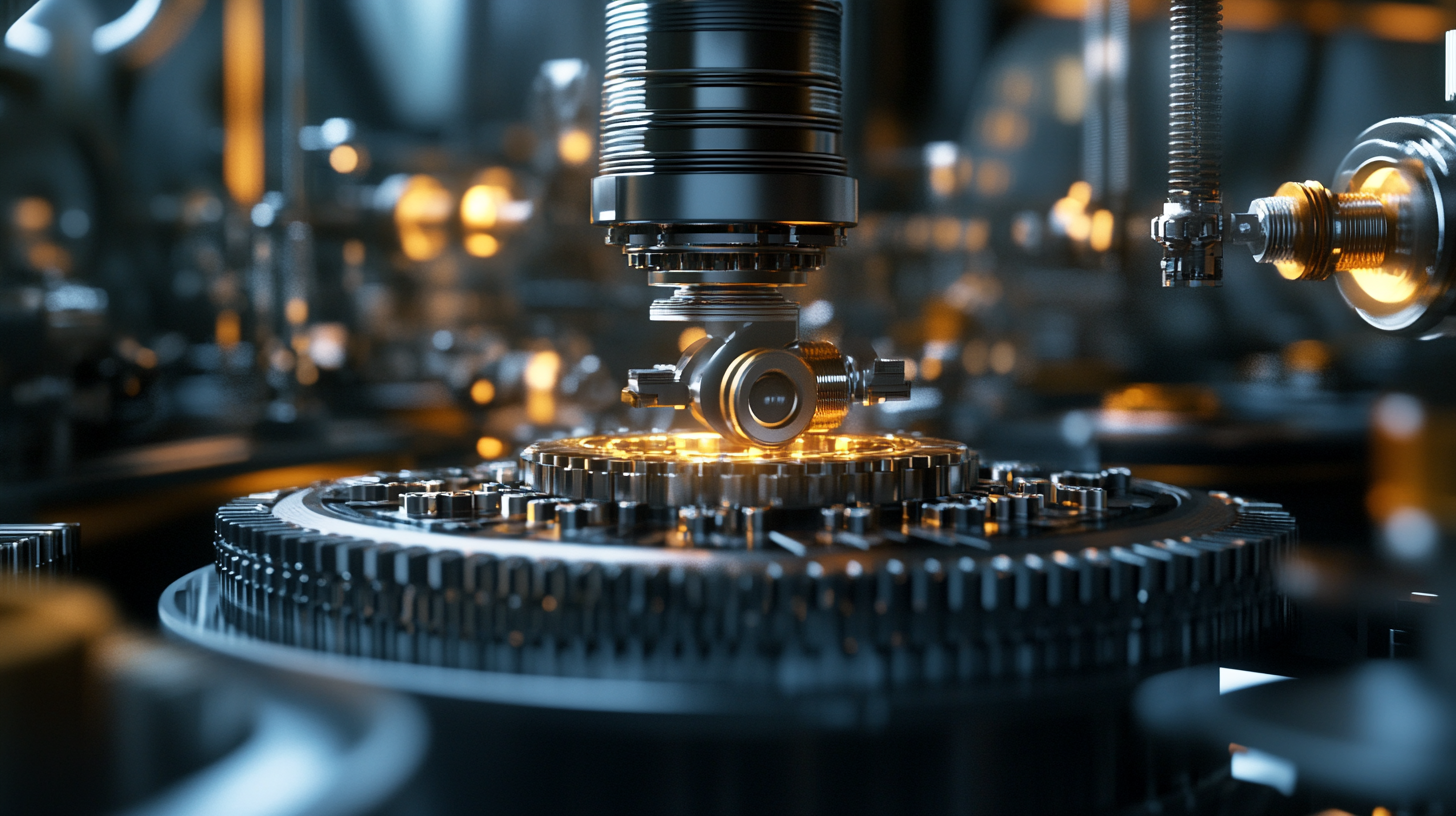

Smart Automation in Packaging Industry

This pie chart illustrates the distribution of various aspects of smart automation impact on the packaging industry.

Ensuring Quality Control through Advanced Technologies

In the rapidly evolving landscape of global packaging solutions, ensuring quality control is paramount. Leveraging advanced technologies not only enhances operational efficiency but also safeguards product integrity at every stage of the packaging process. By implementing sophisticated project management and risk management strategies, organizations can navigate potential pitfalls and streamline operations, ensuring that quality is ingrained in every step.

Moreover, deploying solutions both in the cloud and on-premises offers flexibility and robustness. This approach facilitates real-time data analysis and monitoring, allowing for proactive adjustments to workflows. During the construction phase, from pre-construction assessments to post-build evaluations, utilizing advanced technologies can significantly improve precision and accountability. In the context of smart automation, the integration of tools like 3D machine vision systems amplifies quality checks, ensuring that packaging meets stringent industry standards while optimizing the supply chain for greater efficiency and reliability.

Smart Automation for Global Packaging Solutions

This chart illustrates the quality control metrics achieved through advanced technologies in smart automation for packaging solutions. The data represents the percentage of defect reduction over the past year.

Global Trends in Sustainable Packaging Solutions

The rise of sustainable packaging solutions is a pivotal trend shaping the global market landscape. Consumers today are more environmentally conscious than ever, pushing brands to adopt practices that minimize waste and reduce carbon footprints. As industries respond to this demand, innovations in materials, design, and manufacturing processes are becoming mainstream. For instance, biodegradable plastics and recycled materials are gaining traction, transforming traditional packaging methods into eco-friendly alternatives that benefit the planet.

Smart automation plays a crucial role in the transition toward sustainable packaging. By integrating advanced technologies such as AI and IoT, companies can optimize their packaging processes to enhance efficiency and reduce material usage. Automation not only speeds up production but also ensures consistent quality, allowing for precise control over resource consumption. This synergy between technology and sustainability empowers businesses to meet consumer demands while promoting a greener future, solidifying their commitment to environmental stewardship. As we look forward, embracing these global trends in sustainable packaging will be essential for companies aiming to build trust and loyalty among eco-conscious consumers.

Enhancing Efficiency with Integrated Automation Systems

In today’s fast-paced packaging industry, enhancing efficiency through integrated automation systems is not just beneficial, it’s essential. According to a recent report by MarketsandMarkets, the global packaging automation market is projected to grow from $55.5 billion in 2021 to $88.2 billion by 2026, reflecting a Compound Annual Growth Rate (CAGR) of 9.6%. This massive increase underscores the significance of incorporating smart automation in packaging processes to meet global demand efficiently.

To truly harness the potential of integrated automation systems, businesses can benefit from a few key tips. First, invest in technology that offers real-time data analytics to monitor and optimize production lines. This not only reduces downtime but also improves overall product quality. Secondly, ensure that the automation system is scalable and flexible, allowing for adjustment to varying production volumes and types. As reported by Fortune Business Insights, companies leveraging smart automation have seen up to a 30% increase in production efficiency, demonstrating the powerful impact of technology when paired with smart strategies.

By focusing on these enhancements, packaging operations can achieve higher efficiency, and as reported by Allied Market Research, companies that adopt integrated systems can reduce labor costs by up to 25%. Integrating smart automation solutions is, therefore, not merely an upgrade; it’s a strategic approach to thriving in a competitive marketplace.

Building Trust: The Role of Transparency in Packaging Processes

In today's globalized market, transparency in packaging processes is paramount for building trust with consumers and stakeholders. According to a recent report by Transparency Market Research, the global packaging industry is projected to reach $1 trillion by 2024, underscoring the significance of quality and transparency in maintaining competitiveness. Consumers are becoming increasingly discerning; a survey by Nielsen revealed that 66% of respondents are willing to pay more for products from brands committed to transparency. This shift emphasizes the need for companies to adopt smart automation technologies that improve traceability and clarity throughout the packaging lifecycle.

Smart automation solutions not only streamline packaging operations but also enhance visibility into each step of the process. The use of IoT devices and data analytics enables manufacturers to monitor and report on packaging quality in real-time. A study from Smithers Pira highlighted that automating packaging processes can increase operational efficiency by up to 30%, ultimately leading to a higher standard of product quality. By integrating transparency into their workflows and utilizing smart technologies, companies can build a deeper trust with consumers, ensuring consistent quality that stands out in an increasingly competitive marketplace.