Top 10 Case Packing Solutions for Efficient Operations?

In modern manufacturing and logistics, efficient operations hinge on effective case packing. This process involves grouping products into cases for distribution. Streamlined case packing solutions can significantly impact productivity and reduce errors. Yet, choosing the right system is often daunting.

Various technologies and methods exist for case packing. Some companies struggle to find the best fit for their needs. High-speed machines may lead to faster output but could sacrifice quality. Balancing speed with accuracy is essential. Automation can save time, but it also poses challenges in training staff.

Understanding your unique requirements is crucial. Custom solutions may offer benefits, but they require investment and time. Not all businesses have the same resources or goals. Reflecting on these factors can lead to better decision-making in case packing. Ultimately, the right approach can enhance efficiency and boost overall performance in operations.

Top 10 Case Packing Solutions for Efficient Operations

Efficient case packing solutions are essential for smooth operations. They improve productivity and reduce costs. It’s vital to explore effective strategies for this task. Using automation can significantly speed up the packing process. However, finding the right balance is crucial. Too much automation can lead to glitches and a lack of flexibility.

Another important aspect is the layout of the packing area. A well-organized space can minimize movement and time delays. Consider implementing a standardized process. It may seem tedious, but these small efforts lead to greater efficiency. Regularly training staff on packing techniques also makes a difference. Consistency is key, but sometimes creativity can enhance the process.

Incorporating feedback is often overlooked. Employees have valuable insights into what works best on the floor. Listening to their experiences can highlight areas for improvement. While technology plays a vital role, human expertise is equally valuable. Finding a balance between tech and team input often leads to the best solutions.

Understanding the Impact of Automation on Case Packing Efficiency

Automation plays a pivotal role in enhancing case packing efficiency. By integrating automated systems, businesses can streamline their operations. Machine learning and robotics reduce manual labor. This minimizes human error and speeds up production rates. However, automation is not without challenges. Initial setup costs can be high. Adjustments to existing workflows may also be necessary.

Case packing solutions vary widely. Some systems pack products at a rapid pace. Others focus on precision to avoid damage. Balancing speed and care is essential. Over-reliance on machines might lead to overlooked quality issues. Regular maintenance is crucial to keep systems running smoothly. Operators must stay vigilant to catch potential problems early.

Adopting automation can increase overall productivity. Yet, it demands a thoughtful approach. Workers need retraining to adapt to new technologies. Communication is key to a successful transition. Gathering feedback from employees can reveal areas for improvement. Continuous evaluation of automation’s impact ensures operations remain efficient and effective.

Top 10 Case Packing Solutions for Efficient Operations

| Solution | Automation Level | Efficiency Gain (%) | Suitable Industries | Typical Cost ($) |

|---|---|---|---|---|

| Robotic Arm Packing | High | 30% | Food & Beverage | 50,000 |

| Automated Case Erectors | Medium | 25% | Consumer Goods | 40,000 |

| Case Sealing Machines | High | 20% | E-commerce | 30,000 |

| Carton Loaders | Medium | 22% | Pharmaceutical | 35,000 |

| High-Speed Case Packers | High | 35% | Beverage | 80,000 |

| Pick and Place Systems | High | 28% | Retail | 55,000 |

| Smart Case Packing Systems | Very High | 40% | All Industries | 100,000 |

| Conveyor Packing Systems | Medium | 18% | Manufacturing | 25,000 |

| Bulk Bagging Systems | Low | 15% | Agriculture | 20,000 |

| Flexible Film Packaging | Medium | 20% | Snacks & Confectionery | 30,000 |

Analyzing Cost Savings Through Advanced Case Packing Technologies

Case packing technologies play a vital role in improving operational efficiency. Advanced systems help streamline packaging processes, reducing time and labor costs. For instance, automated packing machines can handle various sizes and shapes of products. This flexibility leads to improved workflows and faster turnaround times.

Cost savings can be significant when implementing these technologies. They often reduce the amount of material waste and increase packing speed. However, companies must evaluate the upfront investment against long-term savings. Some organizations may struggle with integration. Finding the right balance is crucial.

In exploring options, businesses should consider factors like scalability and adaptability. Not all solutions work for every operation. A customized approach might be necessary to ensure effectiveness. Despite improvements in technology, challenges remain. Trial and error are often needed to find the optimal solution that meets specific needs.

Top 10 Case Packing Solutions for Efficient Operations

This chart displays various case packing solutions and their estimated cost savings compared to traditional methods. The data showcases the efficiency gains from utilizing advanced technologies in case packing.

The Role of Ergonomics in Modern Case Packing Solutions

Ergonomics plays a crucial role in modern case packing solutions. When workers are comfortable, productivity increases. A report from the Occupational Safety and Health Administration (OSHA) indicates that ergonomic improvements can boost productivity by up to 25%. Adopting ergonomic designs reduces strain, which is vital in repetitive tasks like case packing.

Many companies overlook the importance of ergonomics. The National Institute for Occupational Safety and Health (NIOSH) suggests that poorly designed workspaces can lead to higher injury rates. Injuries result in lost time and increased costs. In fact, ergonomically designed workstations may decrease fatigue by 30%. This highlights the need for companies to invest in proper tools and training.

Implementing ergonomic case packing solutions requires careful evaluation. Technology can assist, but human factors remain critical. One study found that up to 70% of workers felt aches after work in non-ergonomic stations. Addressing physical strain can create a more efficient workflow. Continuous assessment and adaptation are essential for long-term success.

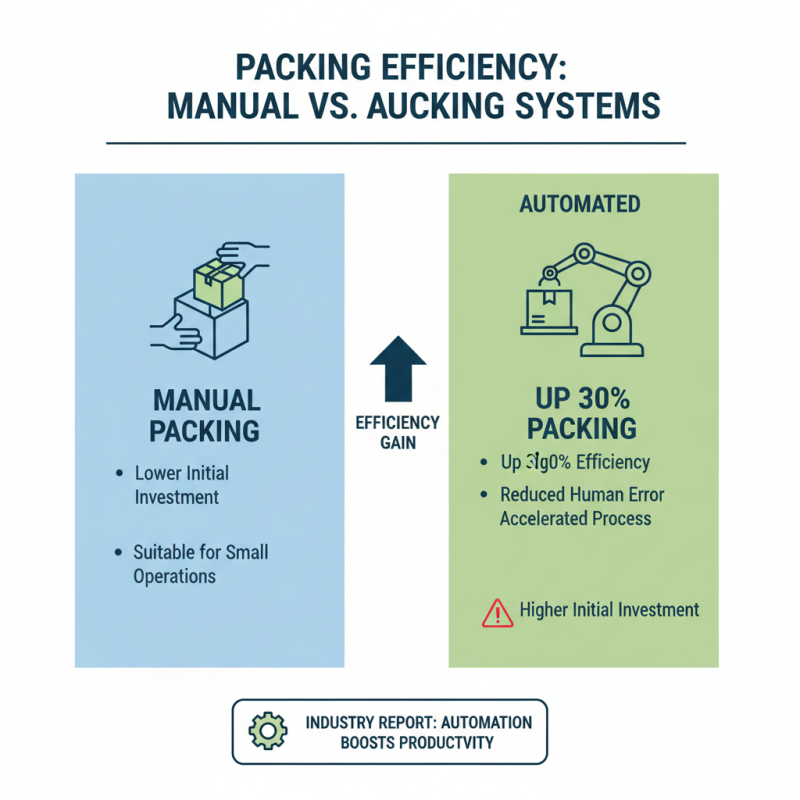

Comparative Study: Manual vs. Automated Case Packing Systems

In the modern packaging industry, the choice between manual and automated case packing systems is critical. A recent industry report reveals that companies using automated systems can achieve up to 30% higher efficiency. Automation reduces human error and accelerates the packing process. However, the initial investment can deter smaller operations, leading them to stick with manual packing.

On the other hand, manual packing systems offer flexibility. Workers can adapt quickly to different product shapes and sizes. But, relying solely on manual efforts can lose consistency. Studies show that manual operations have a higher error rate, averaging 3-5% in mispackaged items. This inconsistency can lead to increased operational costs in the long term.

Moreover, automation is not perfect. Implementing new systems can disrupt workflow during the transition phase. Employees may need training, and delays can occur. The equipment may break down, causing downtime. Such factors must be carefully considered. Balancing costs and efficiency remains a challenge for many businesses. While automated solutions provide speed, manual systems can offer the adaptability that some companies need.

Conclusion

The article "Top 10 Case Packing Solutions for Efficient Operations" delves into innovative strategies and technologies that enhance case packing efficiency. It begins by exploring the impact of automation, highlighting how automated systems can significantly streamline processes and reduce labor costs. Furthermore, the analysis of advanced case packing technologies showcases the cost savings businesses can achieve, while emphasizing the importance of ergonomics in modern packing solutions to improve worker safety and productivity.

Additionally, the article presents a comparative study between manual and automated case packing systems, providing insights into their respective advantages and drawbacks. It also outlines key performance indicators that are crucial for evaluating the efficiency of case packing operations. Overall, the piece serves as a comprehensive guide for organizations seeking to optimize their case packing processes through effective solutions and technology integration.

Related Posts

-

12 Remarkable Benefits of Using a Case Packer Machine in Your Production Line

-

Exploring Innovative Alternatives to Automatic Box Tapers for Efficient Packaging Solutions

-

Understanding the Role of Palletizer Machines in Modern Manufacturing Efficiency

-

Challenges Faced by Global Buyers When Selecting the Best Case Erector

-

Unmatched Quality: China's Leading Exporter of Premier Palletizing Systems

-

The Future of Automated Solutions: Elevating Efficiency with the Best Auto Palletizer