Ultimate Guide to Choosing the Right Case Sealer Machine for Your Business Needs

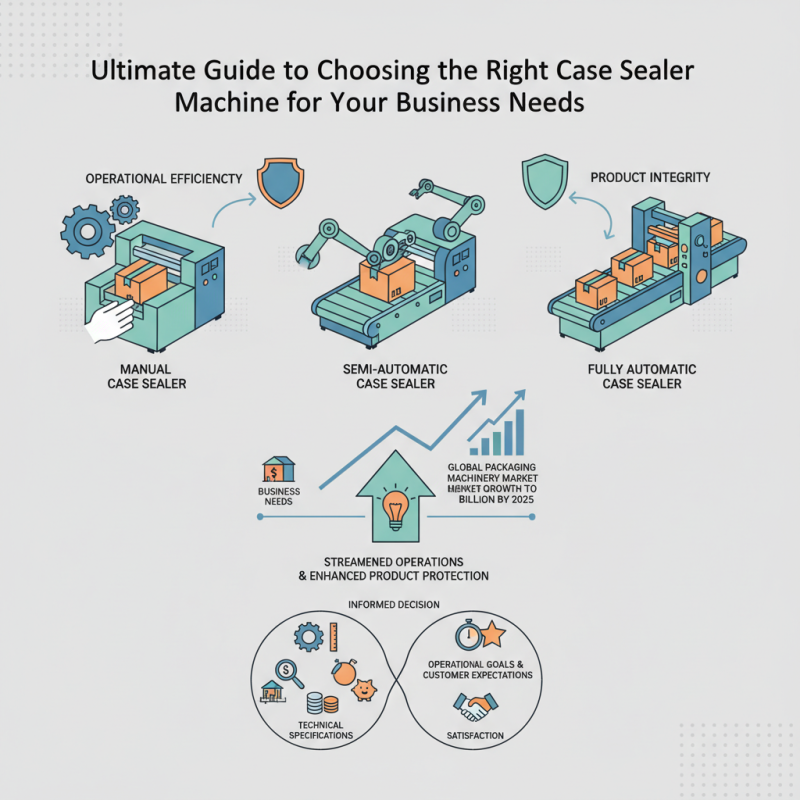

In the fast-paced world of packaging, selecting the right Case Sealer Machine is crucial for optimizing operational efficiency and ensuring product integrity. According to a recent industry report by Smithers Pira, the global packaging machinery market is projected to grow to $50 billion by 2025, with case sealing equipment playing a vital role in this growth. As businesses strive to keep up with increasing demand and productivity, the choice of a Case Sealer Machine can significantly impact the bottom line.

Industry expert John D. Reynolds, a noted author in packaging technologies, remarked, "The right case sealing solution can streamline operations and enhance product protection, allowing businesses to focus on scale and quality." This insight highlights the importance of understanding the various types of case sealers available on the market, as well as the specific needs of one's business. From manual to automatic systems, each option offers unique benefits tailored to different production capacities and product types.

As we delve into the ultimate guide for choosing the right Case Sealer Machine for your business, it is essential to consider not only the technical specifications but also how these machines align with your operational goals and customer expectations. Making an informed decision can lead to enhanced efficiency, cost savings, and ultimately, greater satisfaction for both the business and its customers.

Understanding the Different Types of Case Sealers Available Today

When exploring the various types of case sealers available today, businesses can choose from several options tailored to specific operational needs. The two primary categories of case sealers are manual and automatic machines. Manual case sealers are ideal for smaller operations or businesses with fluctuating volumes, offering flexibility and cost-effectiveness. Conversely, automatic case sealers provide increased efficiency and speed, making them suitable for larger production lines where high output is a necessity. Industry reports indicate that automated sealing solutions can boost productivity by up to 35% compared to manual methods, providing a strong incentive for high-volume operations to invest in automation.

For those considering the right case sealing solution, it’s essential to assess the types of cases being sealed. There are uniform case sealers that handle standard-sized boxes and adjustable case sealers designed for varied dimensions. Additionally, businesses must consider the sealing method – whether pressure-sensitive tape, hot melt adhesives, or water-activated tape suits their product's packaging needs best. Each method has its own advantages; for instance, water-activated tape provides a tamper-evident seal while hot melt adhesives present strong bond properties.

**Tip**: Before investing in a case sealer, evaluate your operational workflow to determine the sealing method and equipment size that best aligns with your packaging processes. Additionally, consider scheduling a demo with suppliers to ensure the machine meets your production requirements and can handle your typical case sizes reliably.

Key Features to Consider When Choosing a Case Sealer Machine

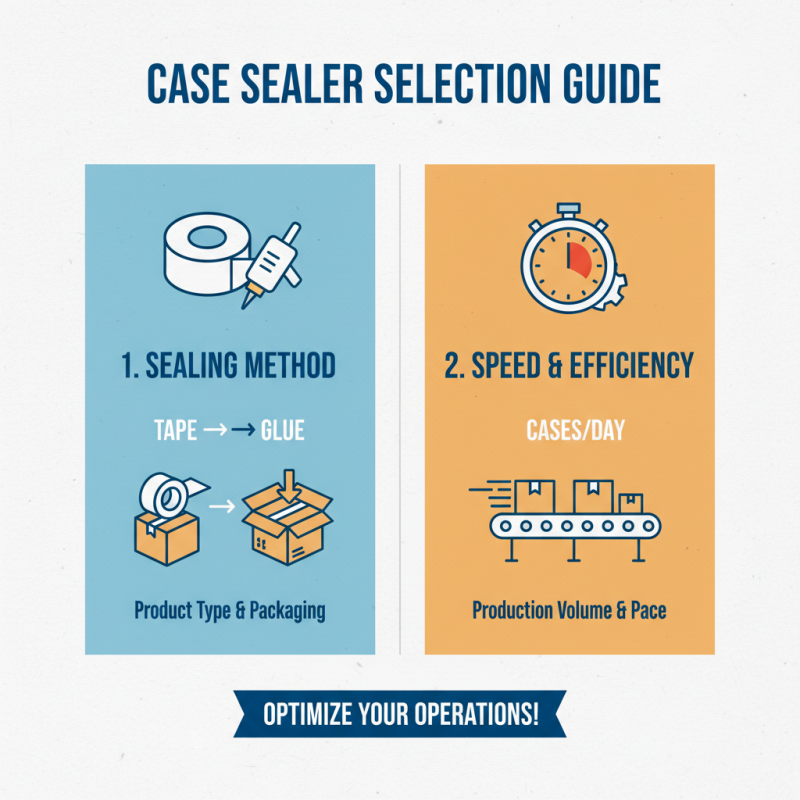

When selecting a case sealer machine, it is essential to consider several key features that align with your business's operational needs. First, the sealing method is pivotal; machines typically use either tape or glue to seal cases. Understanding the product type and its packaging requirements can help determine the most effective sealing method. Additionally, the machine's speed and efficiency are crucial—consider the volume of cases you need to seal daily and choose a machine that can keep up with your production pace without compromising quality.

Another important feature to evaluate is the machine's adjustability and versatility. Many businesses handle various box sizes and shapes, so a sealer that can accommodate multiple dimensions without extensive adjustments can save time and enhance productivity. Furthermore, ease of maintenance and operation should not be overlooked. A user-friendly interface can reduce training time and improve safety. Finally, assess the machine's durability and construction quality, as a robust design will ensure longevity and minimize operational disruptions, making it a wise investment for your packaging line.

Evaluating Throughput Requirements: How Much Volume Do You Need?

When selecting a case sealer machine, evaluating your throughput requirements is crucial to ensure that the equipment meets your business's operational needs. Throughput refers to the number of packages that can be sealed within a specific period, which directly impacts efficiency and productivity. Start by analyzing your current and projected packaging volumes. Consider peak seasons and fluctuations in demand that may require a machine capable of handling higher volumes without compromising quality.

Assessing throughput also involves understanding the types and sizes of packages you will be sealing. Different case sealer machines cater to varying dimensions and weights, so it's essential to choose one that can accommodate your most common products. Additionally, consider factors such as the speed of the sealing process and the time taken for setup and changeovers between different package types. By thoroughly evaluating these aspects, you can select a case sealer that aligns with your throughput needs and supports your business's growth over time.

Assessing the Total Cost of Ownership for Case Sealing Equipment

When selecting a case sealer machine, one of the most critical aspects to consider is the total cost of ownership (TCO). TCO encompasses not just the initial purchase price, but also the ongoing expenses associated with maintenance, operation, and potential downtime. Understanding these costs ensures that businesses make informed decisions that fit their budget and operational needs. Factors such as energy consumption, the frequency of repairs, and availability of replacement parts play a significant role in determining the overall cost effectiveness of the equipment.

In addition to direct costs, it’s essential to evaluate the impact of the case sealing equipment on productivity and labor requirements. A machine that maximizes efficiency can lead to reduced labor costs and increased output, thereby offsetting the initial investment over time. Moreover, businesses should consider the flexibility of the equipment to handle various packaging sizes and styles, which can mitigate the need for future expenditures on additional machines. By assessing these elements carefully, businesses can choose a case sealer that not only meets their immediate needs but also proves to be a valuable asset in the long run.

Industry Standards and Compliance: Ensuring Your Case Sealer Meets Regulations

When selecting a case sealer machine for your business, understanding industry standards and compliance is crucial. Different industries have specific regulations that govern packaging and shipping practices, and using a case sealer that adheres to these standards ensures not only legal compliance but also enhances the safety and quality of your products. These standards may include requirements for material specifications, machine safety features, and environmental considerations that protect both your products and the end consumers.

Tips: Ensure that your case sealer machine is compliant with relevant industry regulations by consulting with experts or industry bodies. This can help you avoid costly fines and ensure that your packaging meets quality benchmarks. Additionally, look for machines equipped with safety features to protect operators and reduce workplace hazards.

Regular maintenance and inspections are essential to ensure that your sealing equipment continues to meet industry standards. Maintain detailed records of these inspections, as compliance can often involve audits and verification processes. Furthermore, training your employees on the importance of compliance and how to operate the case sealer correctly will foster a culture of safety and accountability within your organization.

Case Sealer Machine Compliance Ratings

Related Posts

-

How to Identify Reliable Suppliers for the Best Case Sealer Without Compromise

-

Unlocking Excellence: The Comprehensive Guide to Sourcing Top-Notch Case Sealers for Global Procurement

-

Exploring Industry Trends and Innovations at the 2025 China Import and Export Fair Case Sealer Insights

-

10 Innovative Uses of Case Tapers That Every Global Buyer Should Consider

-

Discovering Innovative Alternatives to the Best Automatic Case Sealer for Your Packaging Needs

-

Adhering to Industry Standards: How to Choose the Best Automatic Case Sealer for Optimal Efficiency